Rigging and using a compressor test cord to manually operate a compressor

One of the many things that can make a refrigerator warm up is the compressor is trying but failing to start. You may occasionally hear this type of noise from the back of the refrigerator (starts about 15 seconds in):

This is the sound of your compressor trying, but failing miserably, to start. Best case scenario: Bad compressor start relay. Worst case scenario: open compressor start winding or seized compressor bearing == buy a new refrigerator.

Question: How do you tell which is which?

Answer: Compressor test cord.

Question: What's a compressor test cord and how do I make one?

Answer:

Question: How do you know which is the start, run, and common connection posts on the compressor?

Answer: Use Brother Bobice's procedure for identifying the compressor electrical terminals:

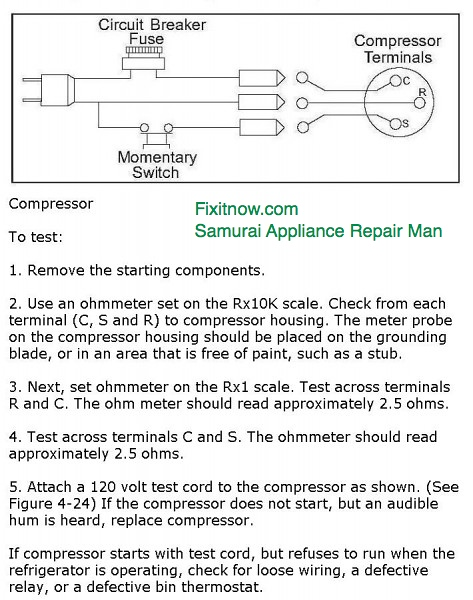

Using a good multimeter set on ohms, remove the compressor terminal cover with the unit off.

Touch one lead (of the meter) to one terminal and the other lead (of the meter) to one other terminal and record your reading . Lets call these terminals (A) and (

. The remaining terminal lets call ©

So for example A-B=7 Ohms

Now lets read A-C and record. Lets say 5 Ohms

Now lets read C-B and record. Lets say 12 Ohms

Now lets add all the A’s= 12 Ohms

Now lets add all the B’s=19 Ohms

Now lets add all the C’s=17 Ohms

The highest reading will be the “Start” winding

The next highest reading will be the “Run” winding

The lowest reading will be the “Common” winding

Therefore B= “Start”

The next is C=”Run”

The remaining terminal A= “Common”

-

.png) 3

3

9 Comments

Recommended Comments