Know your Multimeter: a Short Breakdown of Every Meter Function

Let's take a look at a multimeter and talk about what each function does and what it's good for. This is specifically for a Fluke 116 multimeter, so if you have a different meter, you might see a slightly different array of functions. But this will be representative of a typical multimeter.

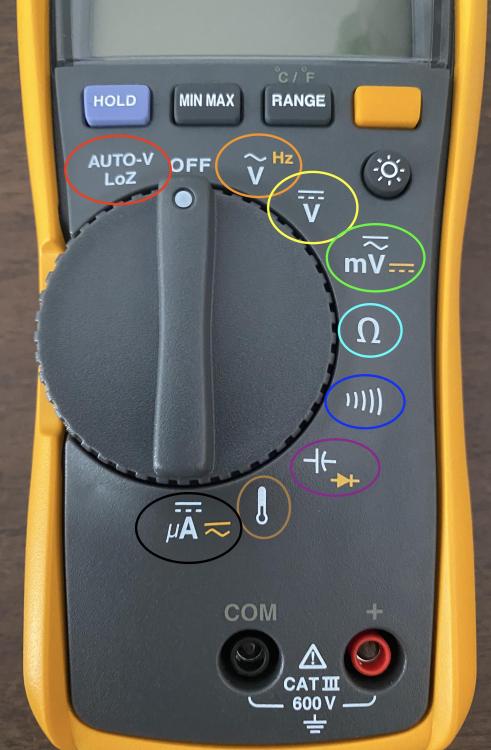

LoZ: That stands for "low impedance". This is the loading function of your meter, meaning that it allows you to do voltage measurements that actually put a load on the circuit, allowing for a small amount of current flow. When it comes to AC voltage, this should be your go-to setting. LoZ keeps you from getting tripped up by ghost voltage and open neutrals, since it will not give you a good voltage reading unless the circuit is actually capable of carrying current. The AUTO-V means that, on this setting, the meter will automatically detect if you're measuring AC or DC voltage.

V (AC): A non-loading AC voltage measurement. Very rare that you would ever use this in preference to LoZ, since VAC is a less reliable setting. If you press the yellow button on the meter, you can use this setting to measure frequency.

V (DC): A non-loading DC voltage measurement. Pretty self-explanatory -- use it when you're measuring DC voltage. Even though LoZ is capable of measuring DC, you almost never want to load down DC circuits that you're measuring, since they're very often low-voltage data lines or the like. So this should be your go-to for DC measurements.

Millivolts: For measuring very small voltages. Rarely used, but there if you need it. Pressing the yellow button switches it to DC millivolts.

Ohms: If you need to measure ohms, this is your setting. That symbol, in case you're not familiar, is the Greek letter Omega, which is used to represent ohms. Resistance measurements are sometimes necessary, and sometimes useful, but they're generally one of the less reliable tools in your meter's toolbox. Whenever possible, use a live voltage measurement instead of an ohms measurement. Or, even better, do a current measurement! Both voltage and current are more reliable measurements than ohms.

Continuity: What this really is is just a dumbed-down ohms measurement. If it detects ohms below a certain threshold (which will vary from meter to meter), then it will beep, indicating that there is continuity between the two points your leads are on. If it doesn't beep, no continuity. Quick and dirty, and sometimes handy. But it's just an ohms measurement wearing a different hat, and so it suffers from the same drawbacks.

Capacitance: A very situational reading, but an incredibly handy one when its time comes. Put your leads on either side of a capacitor, and your meter will tell you its capacitance. Much more reliable than the old-skool way of testing capacitors using an ohmmeter. Pressing the yellow button switches this setting to measuring whether a diode is in spec -- another situationally useful setting.

Temperature: Not all meters will have this one, but it's a very nifty feature to have. Just plug in your thermocouple, stick it into an oven cavity, and you can monitor temperatures with extreme precision. Great troubleshooting oven temperature complaints.

Microamps: Usually, you want to use a dedicated amp-clamp meter for measuring current. But if necessary, this setting lets you measure small amounts of current (both AC and DC) using your meter probes.

There you have it -- a fully-guided, technicolor tour of your multimeter. Did you enjoy the ride? This is just a small example of the high-quality technical education that we provide with our online, self-paced appliance repair training courses over at the Master Samurai Tech Academy. Click here to check out our courses and enroll today.

-

.png) 11

11

5 Comments

Recommended Comments