GE dryer dead

This is a "box style" dryer- you know, it matches the front load washer. The complaint on my work order was "Sometimes works, sometimes doesn't. Now not working at all." I'm going in thinking a motor over-heating, maybe a motor relay on the mudderboard.

Arrive to find the young lady and her newborn. She says, "My husband took it apart and can't figure it out. He thought it was a loose connection and it kinda worked for a little bit, but not really. And now it doesn't work at all." Yay me. Open the garage door to a machine that is 50% disassembled. Console off, lid off, front off, all the screws to the rear pane offl, terminal block, water valve... I'm talking he took off stuff that made no sense to take off. The water valve? In fairness he had everything laid out nicely and organized, and all the screws were next to said parts. Soooo, do I bail, or do I dig in??? Hmmmm... nice customer, nice and clean- well air conditioned house, neighborhood that I work in often, nice kitchen appliances, and matching washer. Sure, I'll have a look.

Re-assemble unit and plug 'er on in for a maiden voyage. Dead. Go to the terminal block and find that the screw and lug is stripped on the neutral. And also the L2 screw and lug is stripped" Sheesh! Could it be that easy? Go to van and get parts and get the wiriing secured. Plug 'er in..... nada.... dang it....

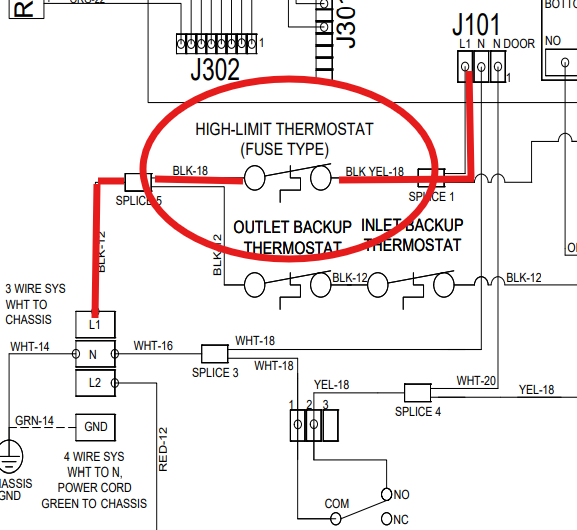

Well, let's start looking. Bust out the skewed-matic and my reader glasses.... Let's see, L1 to board at the J101. Any voltage there? Nope. Hmmm. I see a "High- Limit Thermostat (Fuse Type)", what the heck is that? So I start looking for that fuse. It's not at the back near the terminal block. It's anywhere that I can see. I follow the wires and they go into the cabinet. Crap.... do I have to take this thing apart after I just put it back together. Yup....

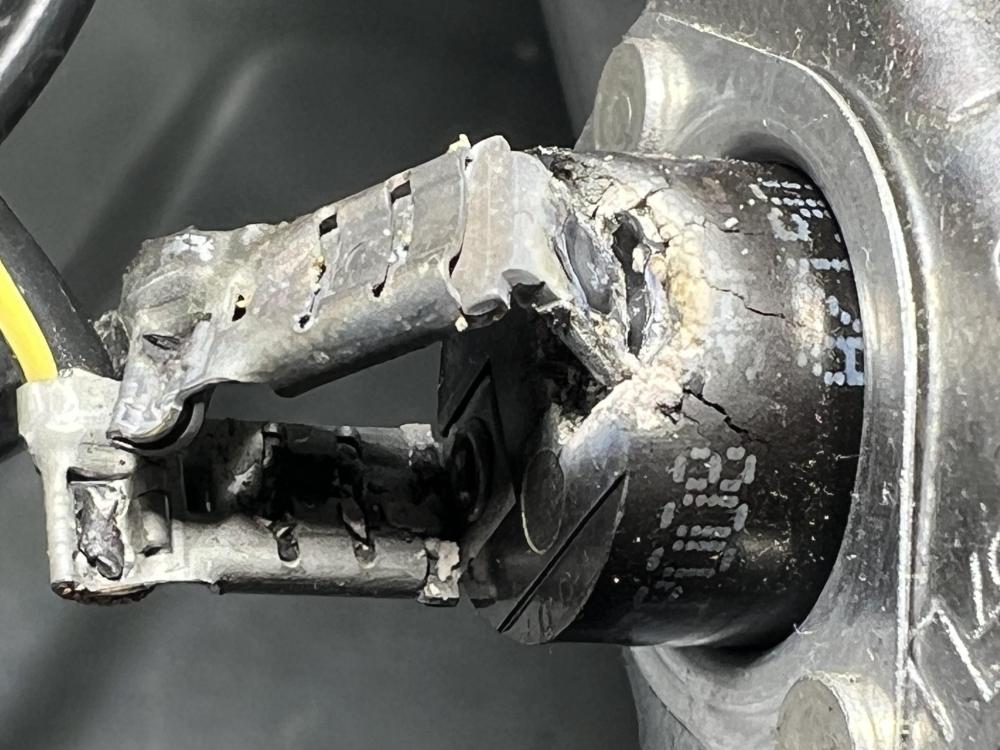

Lo and behold, I find that the aforementioned "High- Limit Thermostat (Fuse Type)" is the dang Thernal Fuse on the heat canister. Huh? First time seeing that. If that thermal fuse opens- it doesn't just kill the heater- it kills power to the board! Lights out homie!

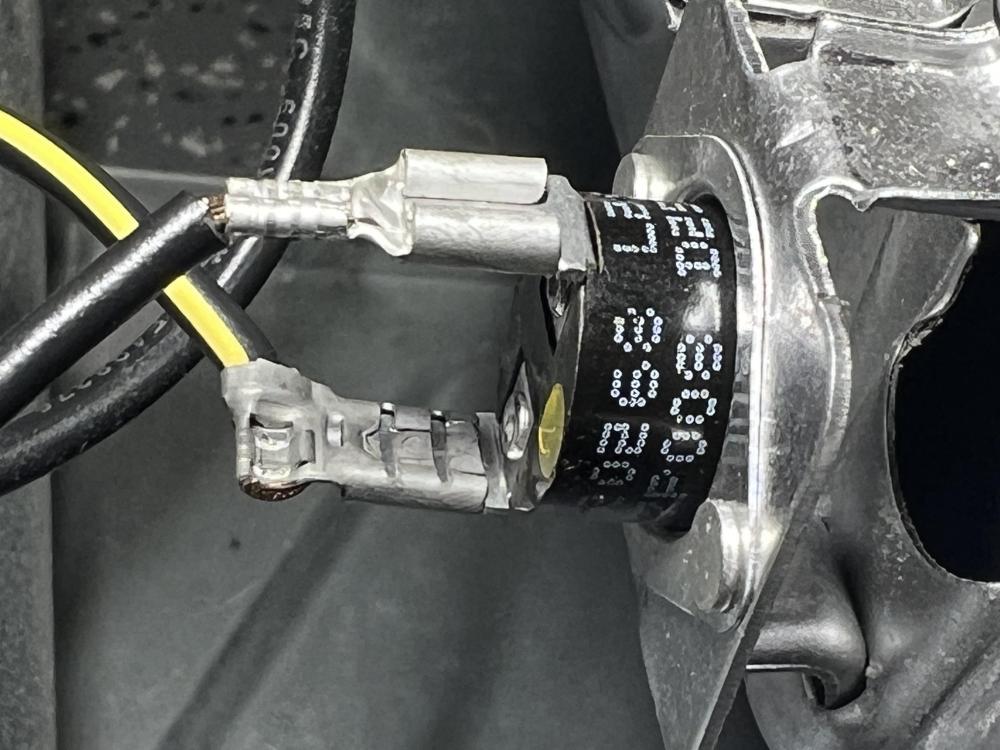

In this case, I found that a terminal on the fuse was charred and not making connection to the biimetal inside. Makes sense now... intermittent working, and finally died. New fuse and new terminal and we back in bidness!

Edited by Koi Guy

Add pics

-

.png) 6

6

.png.aa21533c6656a1cb054a172848652cb2.png)

2 Comments

Recommended Comments