What Diagnostics Can You Run on a Refrigerator in 30 Minutes?

A tech here in the Appliantology forums ran into a Whirlpool dual-evaporator refrigerator with a frozen fresh-food evaporator, and it caused him to ask the following question about troubleshooting it:

QuoteSo if you have 9 calls a day leaving you 30 minutes or so to diagnose these Whirlpool side by sides, what steps are you taking?

Sounds like a fun challenge -- let's figure out how much testing we can get done in a 30-minute service call.

The name of the game when it comes to saving time is keeping disassembly to a minimum. All of our troubleshooting techniques will either require no disassembly, or they'll be done from a single, central point: the control board in the machine compartment at the back of the unit, behind just a few screws.

Airflow

In this dual-evap unit, the fresh-food evaporator doesn't have a defrost heater. Instead, the control does an "air defrost", where it simply stops sending refrigerant to the fresh-food evaporator for a time to let it thaw on its own. So the first thing we'll focus on is airflow.

Check for any gaps or leaks in the gaskets and liners. Air infiltration = excess moisture freezing on contact with the evaporator.

One particular place to check is this area:

Thermistor

If there are no air leaks, the next order of business is to see if the control is running the air defrost often enough and long enough. Our key player here is the refrigerator compartment evaporator thermistor. If that's out of spec and telling the control that the evaporator is warmer than it actually is, then the control will not run defrost as often as needed.

You might think that you could simply run the test for this thermistor in diagnostic mode, as shown here:

But this test only shows you if the thermistor is open or shorted, not if it's out of spec.

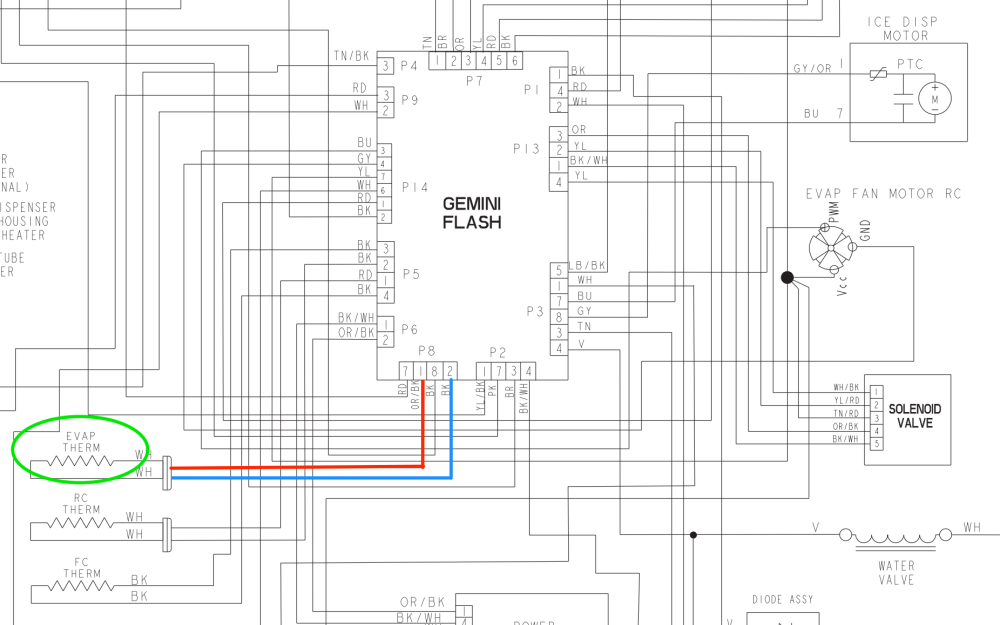

Instead, we should access the control board in the machine compartment and measure the refrigerator evaporator thermistor's resistance.

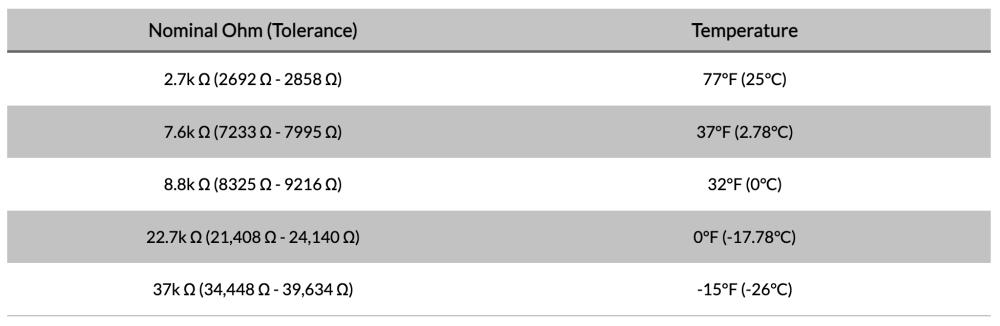

We would then compare the resistance reading we get across P8 pins 1 and 2 to the chart:

If it's out of spec, you've found the issue.

Evaporator Fan

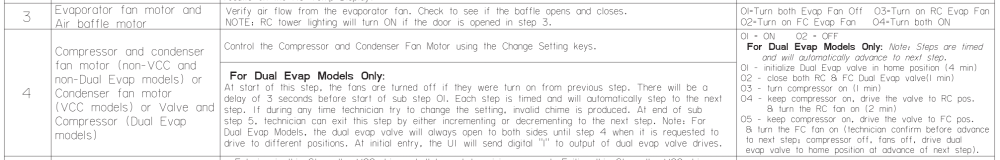

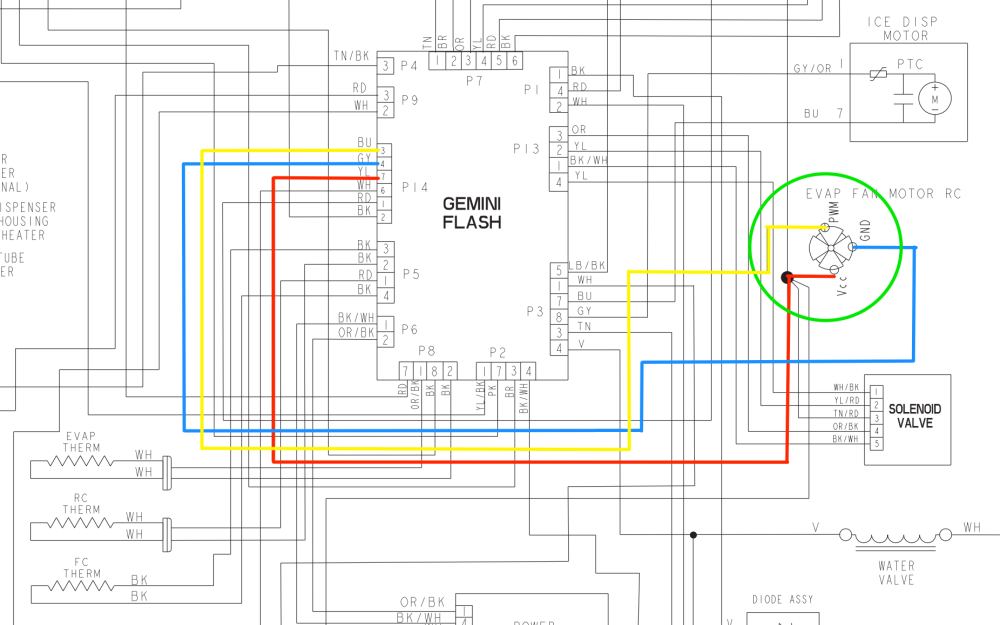

Next up, we need to check that the evaporator fan is running properly. This can also be done from the control board -- first, initiate test 3 in diagnostic mode to turn on the evaporator fan. If you hear it run, you know it's good.

If it doesn't run, check for 14 VDC from P14-7 to P14-4 -- that's the DC voltage supply. If that's good, check for the PWM signal from P14-3 to P14-4 -- that's the speed signal that tells the fan how fast to run. You should measure something between 1 and 10 VDC. You need both of these voltages for the fan to run.

3-Way Valve

Our last step in our half-hour journey will be the 3-way valve. If this is not properly stopping refrigerant from moving through the fresh-food compartment evaporator during defrost, then frost will simply continue to collect.

Our test is pretty simple here: initiate step 4 of the test mode, then put a finger on the body of the 3-way valve (it's also accessible in the machine compartment, just like the control) Every time it changes position, you should feel it vibrate. No vibration = no valve operation.

As you can see, a thorough diagnostic plan doesn't need to take long, nor does it need to involve a bunch of disassembly. We just performed a bunch of informative tests, all either from the front of the unit, or from one easily accessible location. With an efficient troubleshooting plan, getting to the root of a problem like this doesn't need to take any longer than 30 minutes.

Want to get in on the action? Join the Brotherhood of Techs at Appliantology.

- Appliantology.org is a cultivated, private community of techs.

- Get solid tech advice from working, professional techs and business owners.

- Avoid the endless noise and guesswork thrown at you from groups on social media.

- Download the service manuals, tech sheets, and service bulletins you need to git 'er done.

Join the Brethren in the Craft right now with our membership options at Appliantology and see how it can help you in your business starting today.

-

.png) 4

4

3 Comments

Recommended Comments