The Simple Secret Behind this Maytag Dryer Timer that Won't Advance

We've got a toughie for you to figure out today. The tech in this scenario has been out on this dryer multiple times now, and the problem just won't go away. The heating element keeps going open, and the timer motor keeps stalling and not completing cycles. He's verified a good 240 VAC power supply to the timer and replaced both parts multiple times, but the problem keeps recurring every few months. What gives?

Let's board the train away from PCM-Land and use one of our foundational troubleshooting principles to simplify this seemingly stymieing problem: there's usually only one problem at a time. In other words, it's incredibly unlikely that both parts are failing. Somehow, something is affecting both of them.

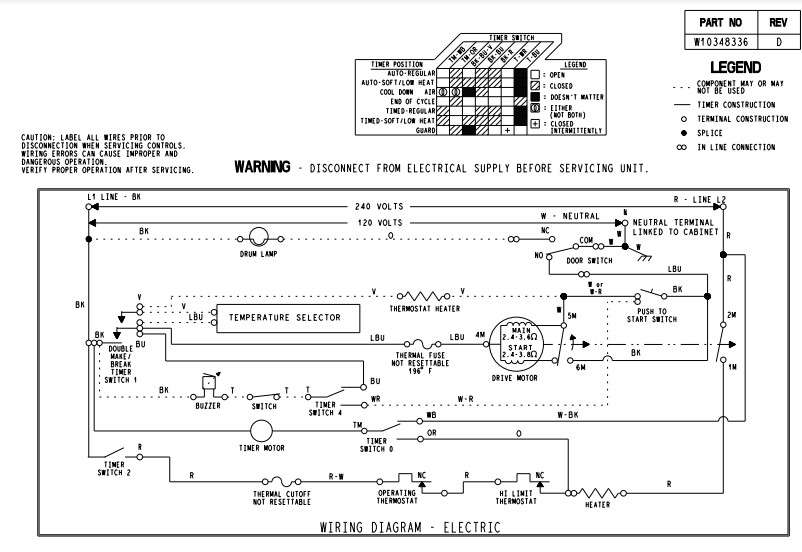

But what's the connection between the timer and the heating element? They're two parts in separate circuits that perform completely different functions. Well, as always, you've got to look at the schematic to get any real troubleshooting done. See if you can spot what's going on...

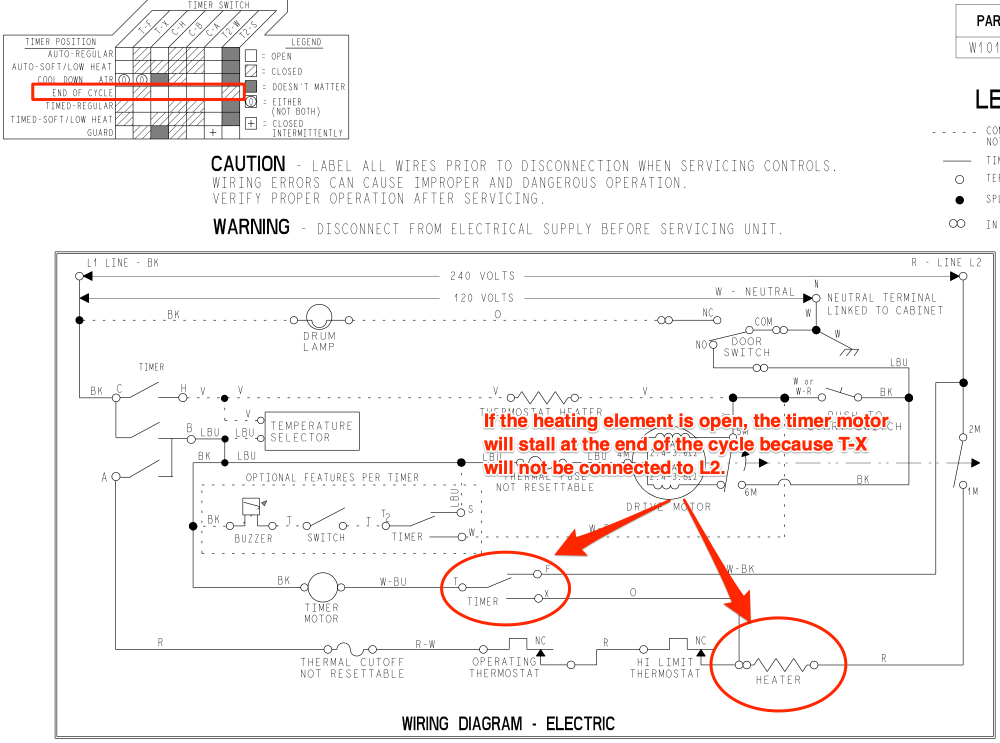

Did you catch it? It's not immediately obvious, but if you study this schematic closely enough, you'll see how one of these seemingly unrelated parts affects the other's circuit. Check out this markup:

During the end of cycle portion of the timer chart, whether it's in timed or auto dry, the timer gets L2 through the heating element. So if that heating element has gone open, it will cause the timer motor to stall at that point. The timer motor was never the problem; it was only ever the heating element.

So why did the element keep failing? As it turns out, this tech learned the hard way about the dangers of using non-OEM parts. He had been installing third-party elements that just didn't cut it after a few months of operation. Lesson learned, and a great demonstration of series-circuit trickery in these old-skool dryers for all of us!

Want to learn more about using schematics, timing charts, electrical understanding, and sound troubleshooting strategies to nail the problem every time? Click here to check out our online Washer and Dryer Repair course over at the Master Samurai Tech Academy.

-

.png) 4

4

.png.aa21533c6656a1cb054a172848652cb2.png)

0 Comments

Recommended Comments

There are no comments to display.