Schematic Basics: LG Wall Oven No Heat

Got a short and sweet one for you today. Here's the scenario:

You're troubleshooting an LG wall oven that doesn't heat. You've gone ahead and torn it down as much as you could to do an ohms measurement on the broil element (in spec) and the temperature sensor (also in spec). You confirmed that the unit was getting a good 240 VAC power supply. You wanted to test the bake element too, but you didn't have a second man with you, so you gave up on that idea. Instead, you just replaced the main control board and hoped that would get it.

Unfortunately, you didn't win the lotto this time, and now you're out a control board. What did you do wrong in your troubleshooting, and how could you have done it better?

A couple key issues with your troubleshooting strategy so far: relying on ohms measurements over more reliable voltage or amp tests and performing unnecessary disassembly to do tests. These are PCM moves. To troubleshoot this like a real tech, we need to take the first step any real tech does and look at the schematic.

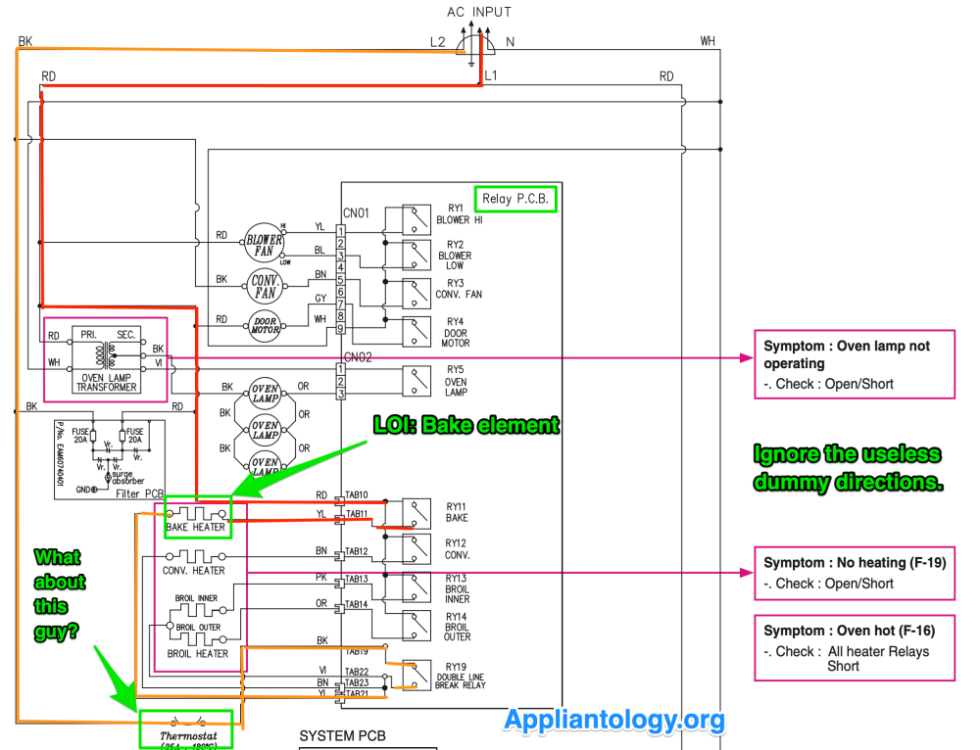

Now that we're looking at the schematic, things become much plainer. I'll explain a couple of terms in the markup.

The LOI is your Load of Interest. That just means it's the load that's not doing what it's supposed to be doing. In this case, we actually have multiple potential LOIs, since all of our elements aren't heating. But that's not a problem -- we just pick one, like the bake element, and make that our LOI. Then we analyze its circuit.

Dummy directions are those pink boxes to the side. These are rarely useful in any tech doc, and these particular ones are extremely unhelpful. Just ignore them.

Now that we're looking at things sensibly, you'll notice that the bake element can be tested right from the relay board, which is pretty easily accessible. No second man required. One meter lead on the bake relay and the other on the DLB relay lets us measure the voltage in the bake element's circuit -- simple as that. If we have a good 240 VAC supply while the oven is on, then we know the relay board is doing its job. That would only leave the bake element as the culprit. But it's very unlikely that that's the case, since all of the elements aren't working. This means we need to find something that has failed which is common to all of them.

You could have a failed DLB relay on the relay board -- but that's not the only possibility. Since we've done a thorough circuit analysis of the LOI's circuit, we've noticed that there's a thermostat in the L2 leg of its power supply. If that's gone open, it will cut off L2 to all the elements.

Yet again, there's no need to disassemble -- a simple test for the presence of voltage at the DLB relay will tell us if the thermostat has gone open or not. And just like that, we're able to positively identify a failed component without any more disassembly than it took to get to the relay board.

Want to learn how to read schematics and troubleshoot like a real tech? Click here to check out our Core Appliance Repair Training Course over at the Master Samurai Tech Academy.

-

.png) 10

10

-

1

1

11 Comments

Recommended Comments