WPL dryer timer- intermittent heat

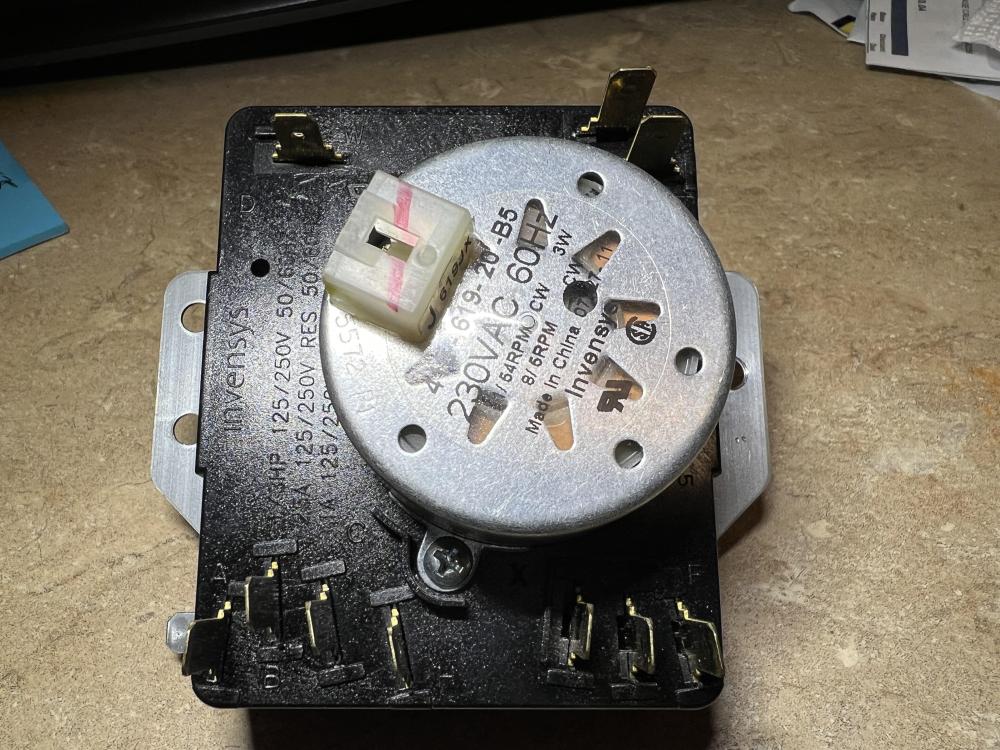

As you’ve probably seen, the new Whirlpool dryer timers have not been very robust and are prone to several failures. These failures include: no heat, intermittent heat, not advancing the cycle, and not ending the cycle.

A service call yesterday was for a “not drying clothes” complaint. Now I normally associate a dryer that’s heating but not drying clothes as a possible exhaust restriction, and that would be my first test- airflow. BUT, when it’s a Whirlpool built unit with a timer- the first thing I do is pull the knob off to see if the timer shaft is plastic or metal. If it’s a plastic shaft- I now have my Spidey senses activated and have to consider the possibility of an intermittent timer failure. My case yesterday was such.

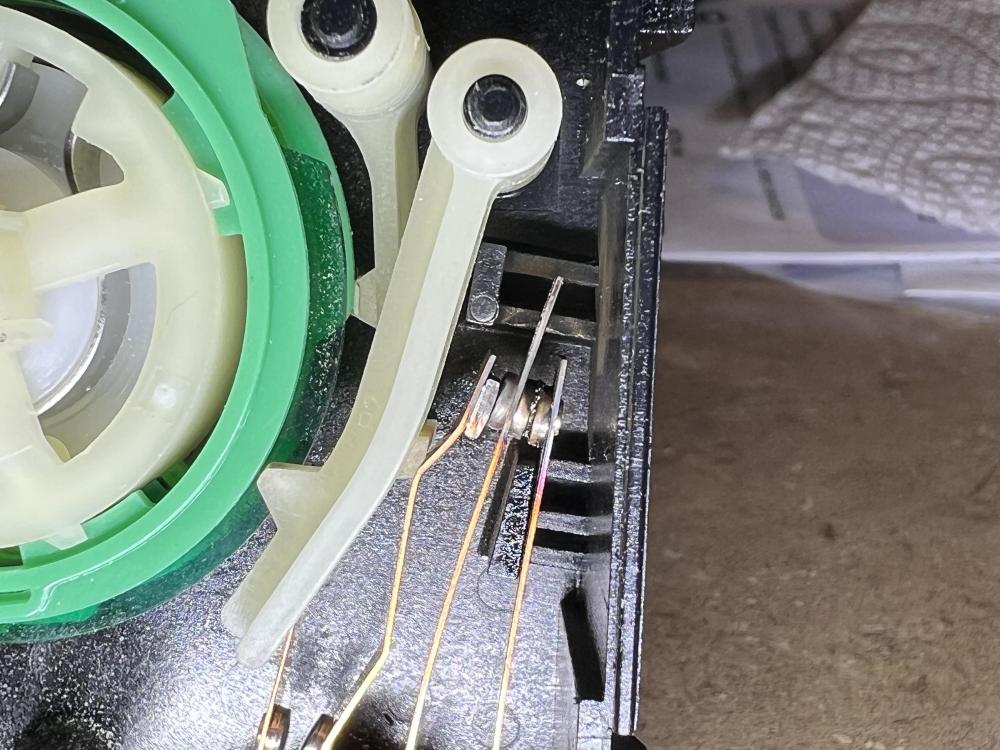

So what is failing on the timer? Let’s look inside!

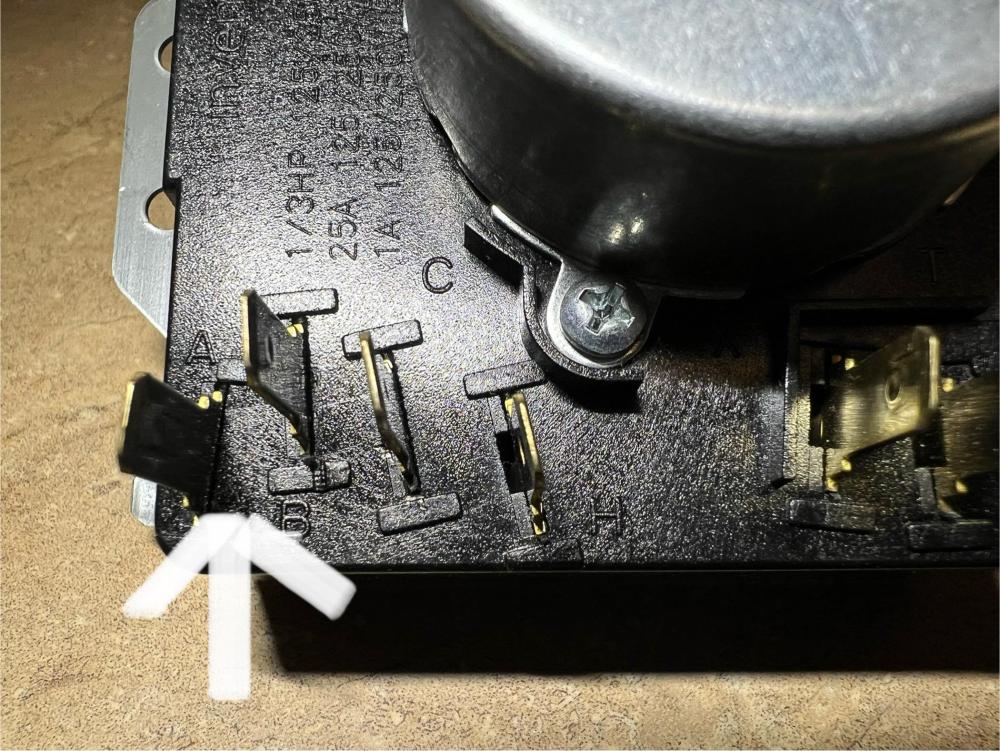

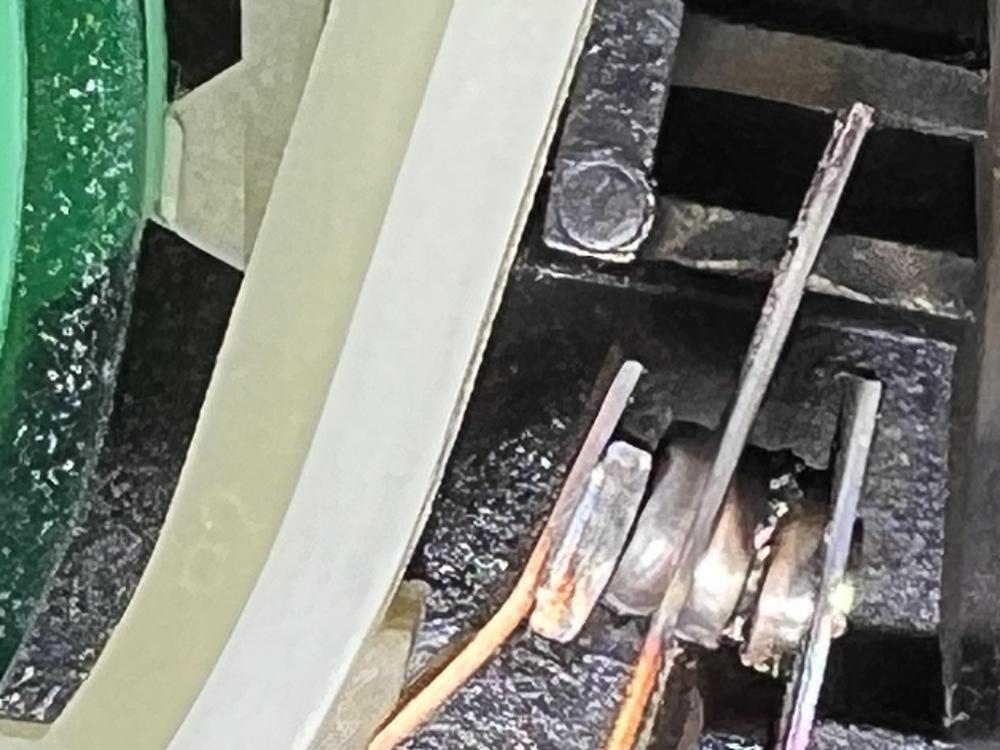

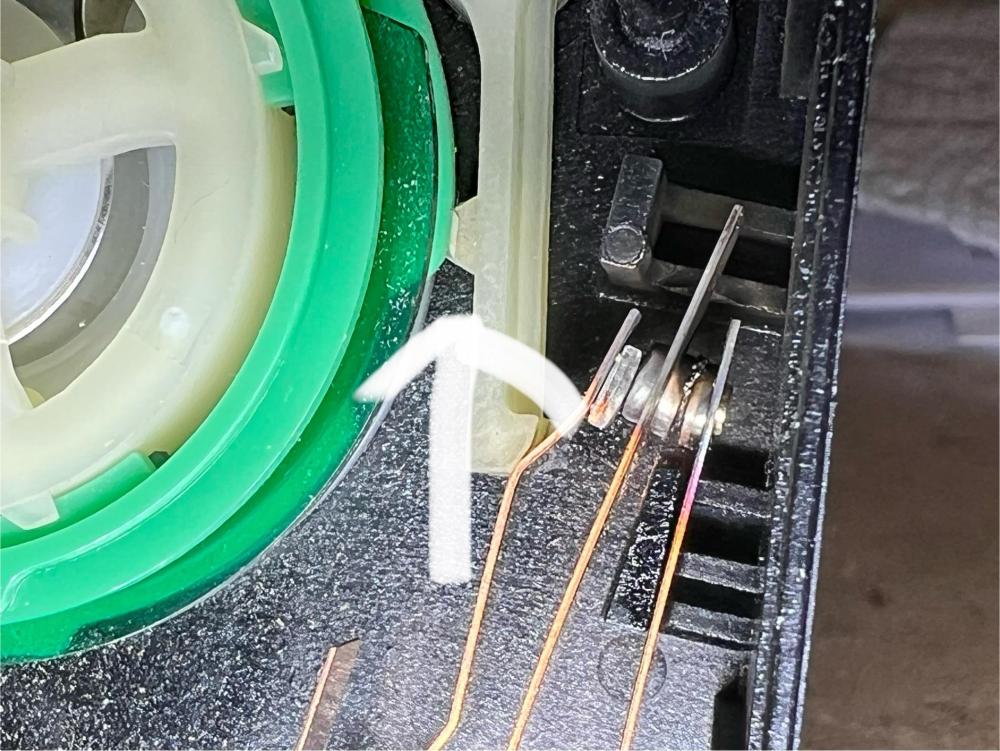

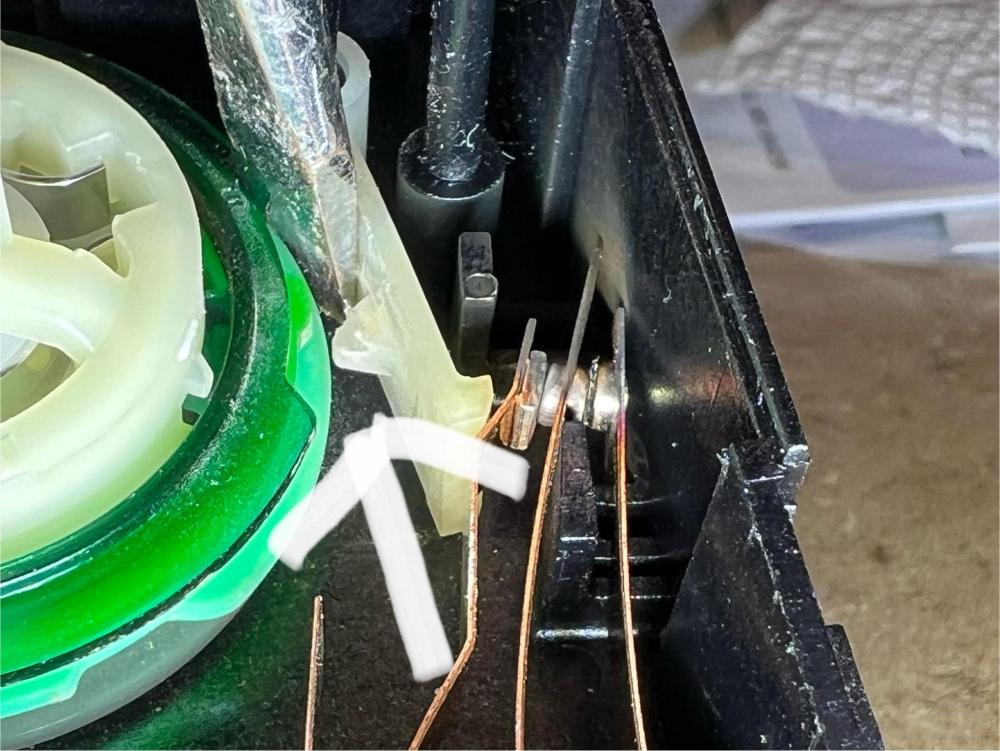

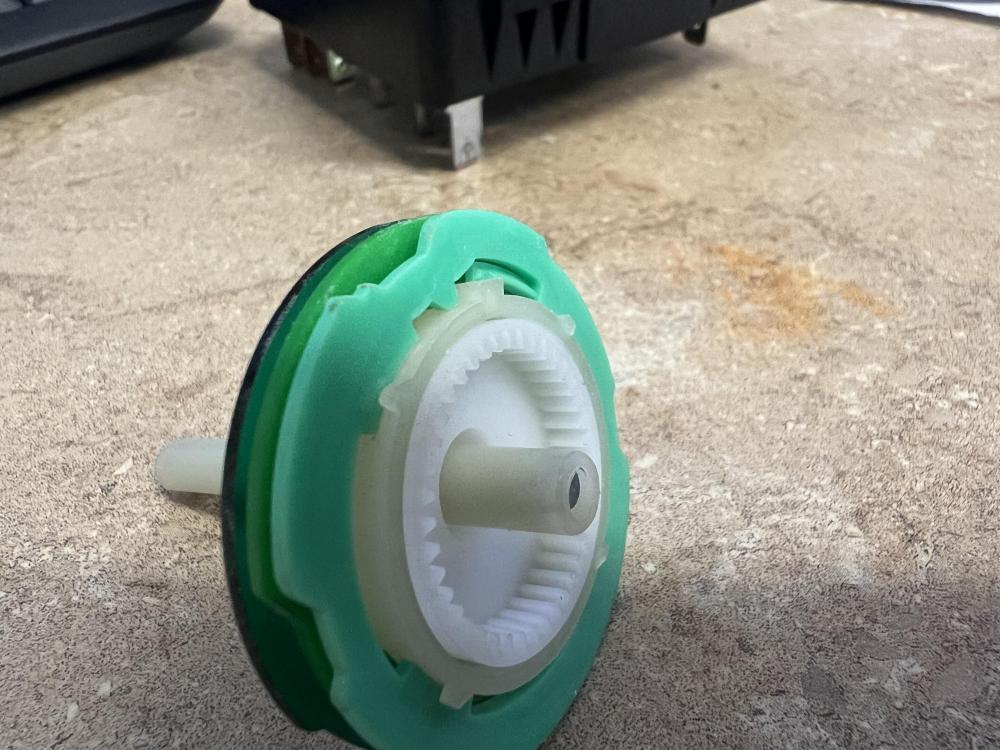

The first thing I see is plastic gears, cams, and reeds. And the they just look cheap and flimsy- and they are. I can see some contacts are pitted and crusty looking. One in particular is the L2 contact. That contact is direct to the heat circuit. Hmmmm…. So when I spin the timer and watch the cams and contacts do their dance- I can see that the reed for that cam is not riding like the rest. When I look closer I see that the point of contact if the reed is worn down. What’s happening is that that L2 contact is being made sometimes, and sometimes not. BOOM SHAKA LAKA!

-

.png) 10

10

-

1

1

.png.62a7d7300de75dfbd19764a318766630.png)

13 Comments

Recommended Comments