What does the run capacitor do in split-phase compressor circuits?

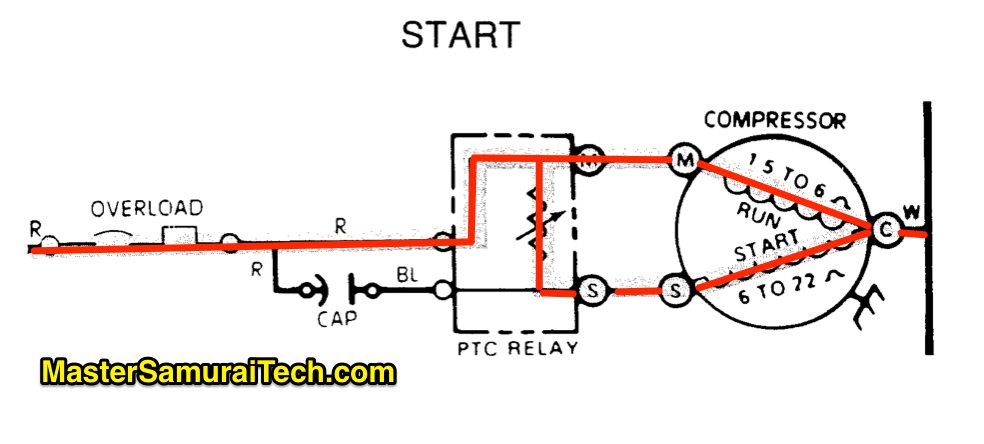

The run capacitor is wired in series with the start winding. When the compressor first starts, the run capacitor is shunted by the closed PTC (or whatever start relay or device is being used) so current just flows through the main and start windings which are in parallel with each other. The start winding is there to create that split-phase magnetic field that's out of phase with the main winding field that rotates around the stator. This rotating magnetic field is what starts the rotor turning from a dead stop.

After the compressor has started and is up and running, the PTC opens which removes the shunt from the run capacitor. Now the run capacitor and start winding are in series with each other and both are in parallel with the main winding.

At this point, the run capacitor does a couple things:

1) limits current flow through the start winding

2) smooths out the back EMF pulses from the main winding.

The net effect of the run capacitor is to reduce the current draw of the compressor while running (which also helps it run a bit cooler) and to help the compressor run smoother and more efficiently.

If the run capacitor were shorted (ie., replaced by a wire), the compressor would still start but the compressor would draw A LOT more current, run very rough, and quickly kickout on thermal overload.

I have never seen a run capacitor fail short.

Learn more about refrigerators and how to troubleshoot them in the Refrigerators training course at the Samurai Tech Academy.

-

.png) 1

1

.png.f1622b6167220d8c8c781a7c863c9adb.png)

4 Comments

Recommended Comments