Dryer Case Studies that will Blow your Mind

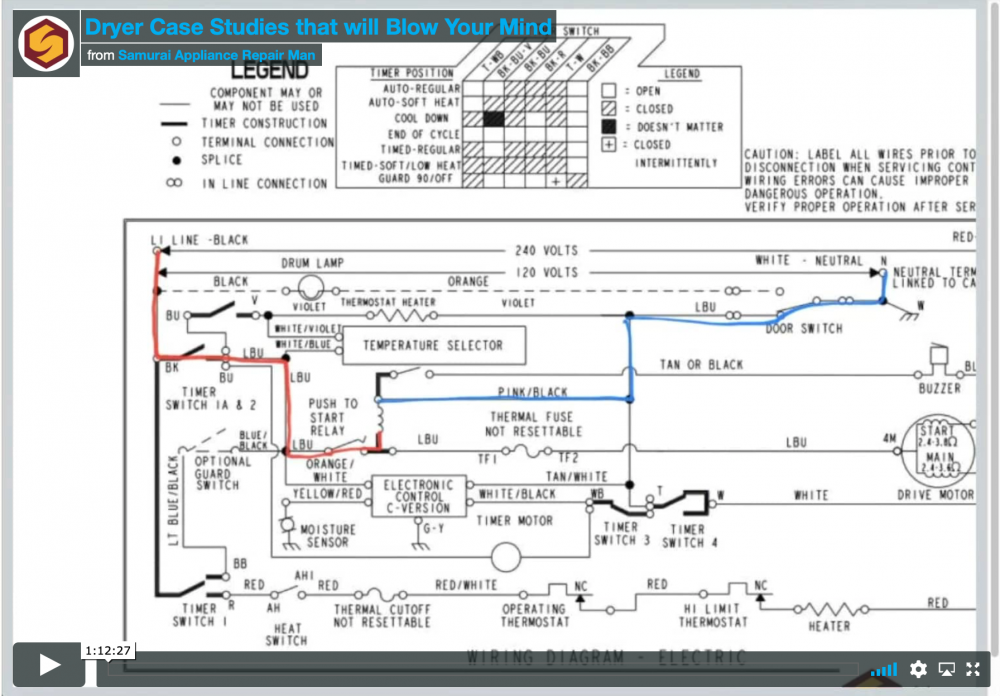

Did you miss our awesome webinar a few weeks ago? With all the computer-controlled dryers out there today, many techs forget that they still need Old Skool circuit troubleshooting skills to solve many dryer problems they'll encounter in the field today. With that in mind, our recent webinar covered four real-world dryer case studies on simple dryer circuits that trip up lots of techs who should know better (and think they do but, in fact, do not).

Some of the topics we covered include:

- Worked through 4 real-world dryer case studies that have faked out today's technicians

- Gained a deeper understanding of basic AC circuits and dryer components like start relays, motor centrifugal switches, and TCOs and how they function in dryer circuits

- Explained the famous “loads in series” configuration and showed it in action

- Illustrated the non-analytical troubleshooting technique of jumping the switch

- Explained how TCOs operate and why they go open

- Explained why amp measurements are always the first SOP move when troubleshooting any AC circuit and especially when a dryer TCO has opened.

- Learned why sharp techs prefer live tests over ohms tests any-freakin-day

Summary of the Case Studies:

Case Study 1:

- How does the push to start relay work in the circuit?

- Does Timer switch 4 always complete the Neutral for the motor regardless of its switched position?

- How does the centrifugal switch function?

- What does the switch below the “Temperature Selector” switch do?

- How does the buzzer operate?

Case Study 2:

- Dryer motor no-go

- Press start button, hear a humming at the start button

- Disassembled the dryer thinking the blower was jammed

- Ordered the start “switch” based on the customer’s “diagnosis”

Case Study 3:

- No moisture sensors

- Is Auto Dry cycle controlled by the timer?

- How does the dryer know when the clothes are dry?

- What component failure could cause this dryer to run and cycle heat but not advance the timer?

- What troubleshooting move should you make to prove the problem?

Case Study 4:

- Dryer no heat

- Tech found open TCO. Replaced both the TCO and Operating Thermostat

- A month later, callback: same problem, replaced same parts

- Next day, another callback: same problem. Noticed terminal on Hi Limit was loose and wire corroded.

- How could he have found the loose connection on the first trip?

All Appliantology premium tech members can watch the full webinar at the link below:

.png.aa21533c6656a1cb054a172848652cb2.png)

0 Comments

Recommended Comments

There are no comments to display.