Prediagnosis: How a Real Tech Prepares for a Service Call

Here at Appliantology, our primary mission is to support appliance repair techs in performing prediagnosis: the method of performing as much troubleshooting as you possibly can before setting foot in the customer’s home. Prediagnosis is the biggest factor in increasing FCC (First Call Complete) rates, and the higher the FCC rate, the higher your company's profitability.

So how exactly does one prediagnose, and how does Appliantology help with that? Well, let's walk through the journey of an Appliantology member prediagnosing a service call.

Step 1: Collect the model number and customer complaint.

This is something you should already be doing for all of your service calls. Once you've gotten these two pieces of information, you then need to verify that the model number is valid, and then boil down the customer's problem complaint into an actual problem statement.

A problem statement is not what the customer thinks is wrong with the machine, nor is it your "best guess" at the problem. This is just you taking what the customer tells you and distilling that into a statement of what the machine is doing that it shouldn't be doing, and/or what is the machine not doing that it should be doing. Simple as that.

Step 2: Look up the tech docs for your model in the Downloads section.

Now that you have the model number, it's time to find the tech sheet or service manual for your machine. And yes, we're doing this right now, well before you drive out to the service call. Why? Because we're putting together a game plan.

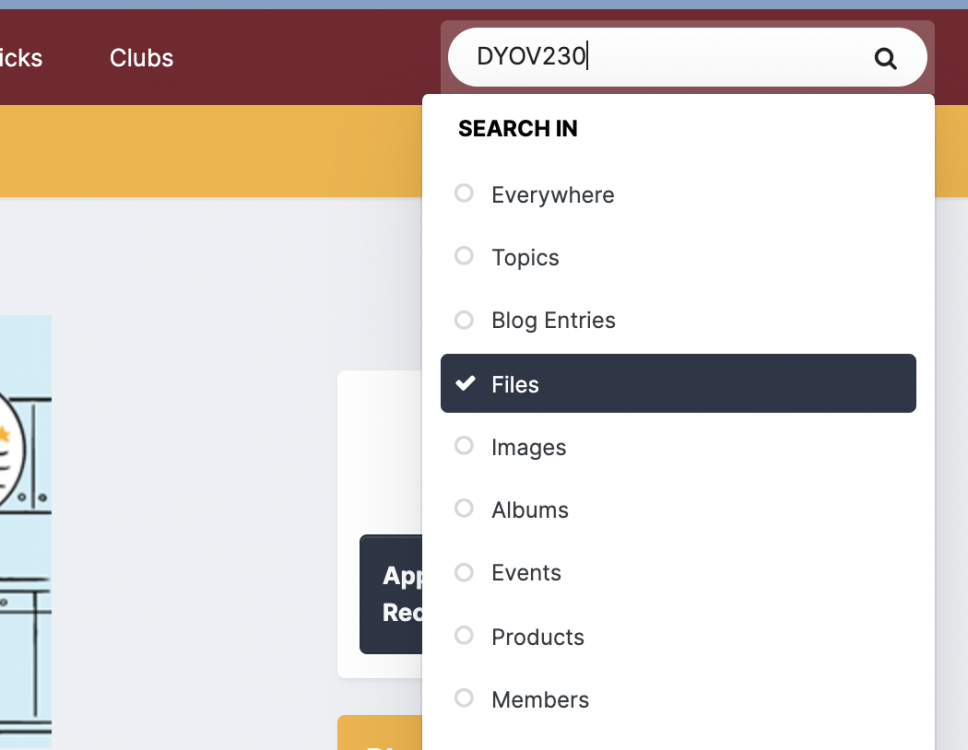

Normally, finding technical docs on the Internet can be a pain, especially with certain manufacturers. Here's where Appliantology comes it. All you need to do is plug your model number into the search bar in the upper right corner of the site and see what comes up. Make sure to select "Files" in the dropdown menu if you're looking for manuals. Click here to visit our FAQ page for more info on searching the site.

We have a massive and constantly growing selection of technical docs for all major US manufacturers, so more than likely, you'll find what you're looking for. And if you don't? No worries. That's exactly what our Service Manual Requests forum is for. Any premium member of Appliantology can requests a manual there, and we'll track it down for them.

Step 3: Perform your schematic analysis and form your troubleshooting plan

Now that we have our info, time to use it. Before we even think about getting in the service vehicle, we're going to figure out what load (or loads) we're going to be focusing on -- our Load(s) of Interest. Furthermore, we're going to do a thorough schematic analysis of the circuits associated with those loads, as well as generally reviewing other useful information about the machine, such as error codes and diagnostic modes.

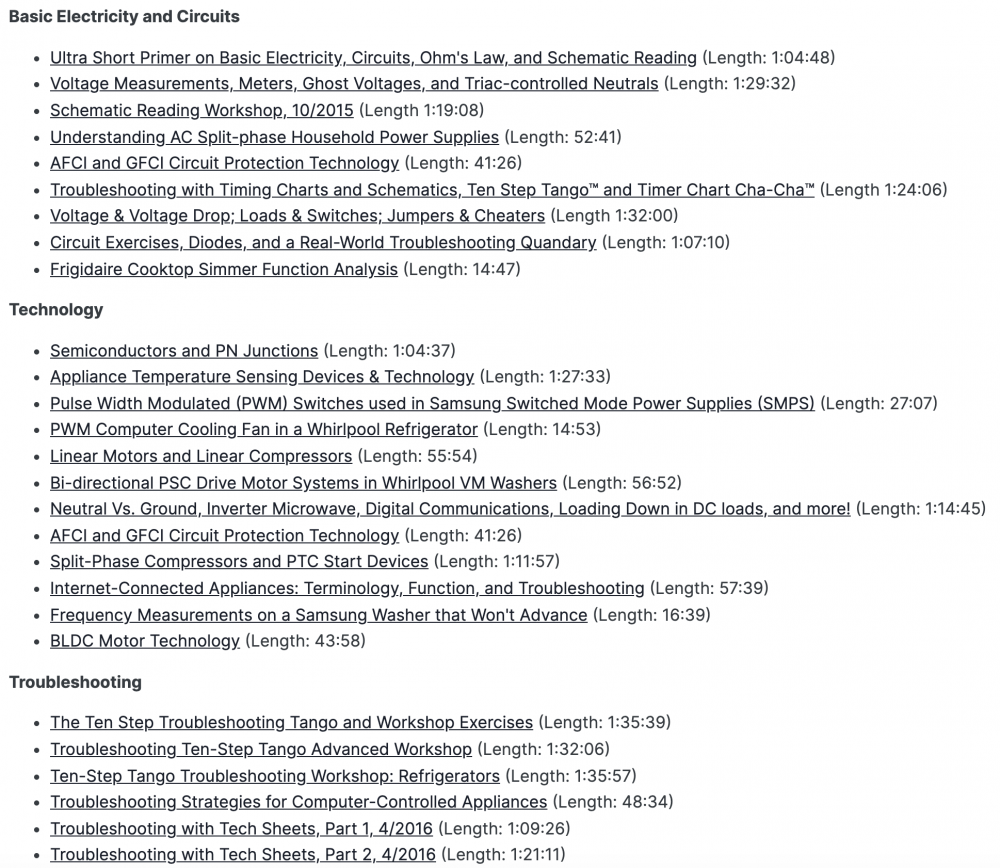

Shaky on how to use a schematic to form a troubleshooting plan? Appliantology has your back again. We have 70+ hours of in-depth technical training videos on-demand for our premium members. These are all our own original content, so you're not going to find them outside of Appliantology or Master Samurai Tech, our training site.

And of course, for tech tips in a more bite-sized format, be sure to follow this very blog.

Step 4: Get advice from other techs.

By now, you've come up with your own informed theories about possible causes of your problem statement through your own technical know-how and your schematic analysis. But maybe you have some questions about your model -- maybe a part of the manual was unclear to you, or you're uncertain what LOIs are indicated by the problem statement.

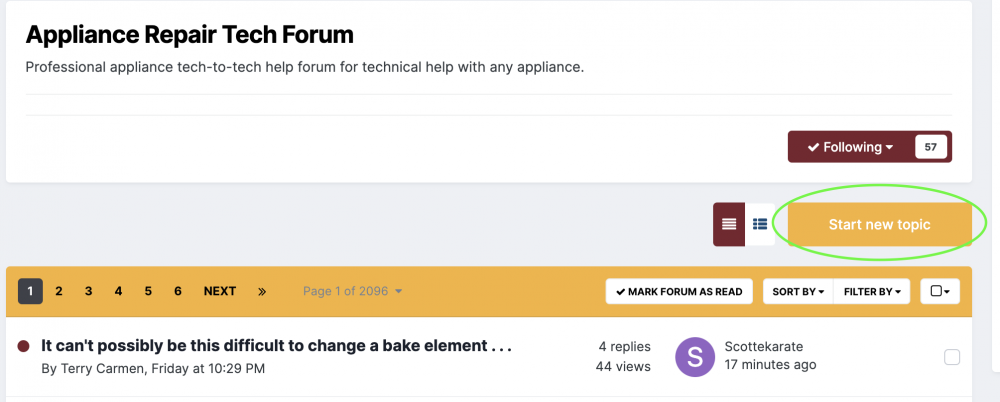

The Appliance Repair Tech Forum is the perfect place for questions like these. Just post a new topic there outlining the problem statement and what troubleshooting you've already done, and the countless helpful techs around the site will chime in with their advice.

You can even use the same search bar you used to find tech docs earlier to search for past topics that other techs have started on similar problems -- maybe someone has encountered something similar in the past and has some wisdom for you.

Step 5: Git 'er done!

Now you're fully equipped for the service call. You've studied the circuits, formulated your theory of the most likely causes of the problem, and figured out how you're going to go about troubleshooting them. That's a lot of work that you don't have to do while the customer is breathing over your shoulder, and trust me, you'll feel the difference like night and day -- so will your profits.

Want to join the Appliantology community and get started prediagnosing like a pro? Click here to check out our tech membership options.

-

.png) 5

5

2 Comments

Recommended Comments