Do Ohms Lie?

"Ohms lie." It's become a popular phrase in the tech community, but what does it actually mean? Should you never do an ohms measurement? Are they completely worthless? Or is this phrase just another example of tech mythology?

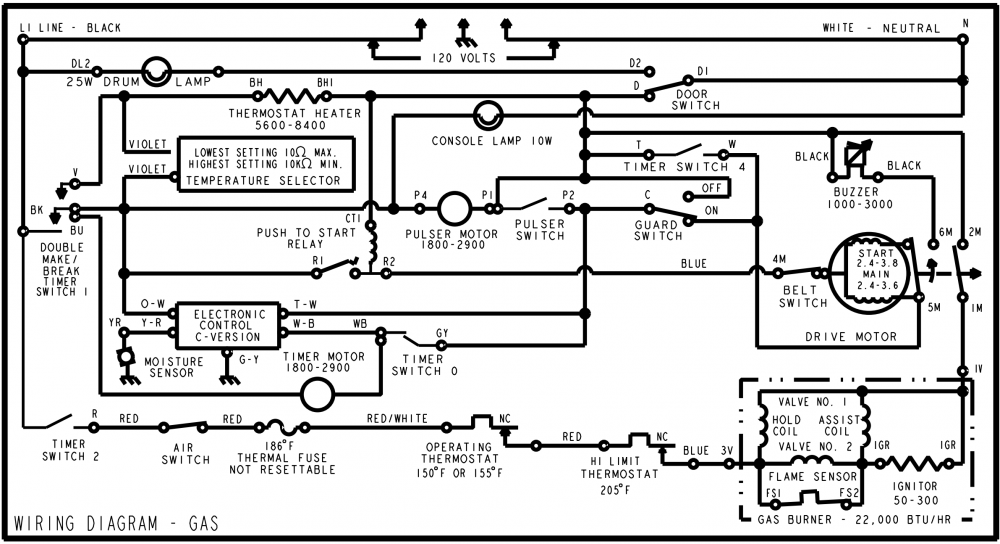

The answer is more complicated than any of that. Let's run through a quick example to demonstrate. This is an old-skool Whirlpool gas dryer, just like they were cranking out left and right in the good old days.

Now, our scenario is a simple one: when we run the dryer on a heat cycle, the ignitor doesn't glow, and we get no heat. We go through and take an ohms measurement of all the relevant components -- the ignitor, the coils -- we even measure the continuity of all the switches and thermal controls. Everything checks out.

How is this possible? If all the components are within spec on ohms, shouldn't the circuit run?

We've been doing all of our tests on a dead machine, since you can't do resistance measurements on a live circuit. Why don't we try a live test?

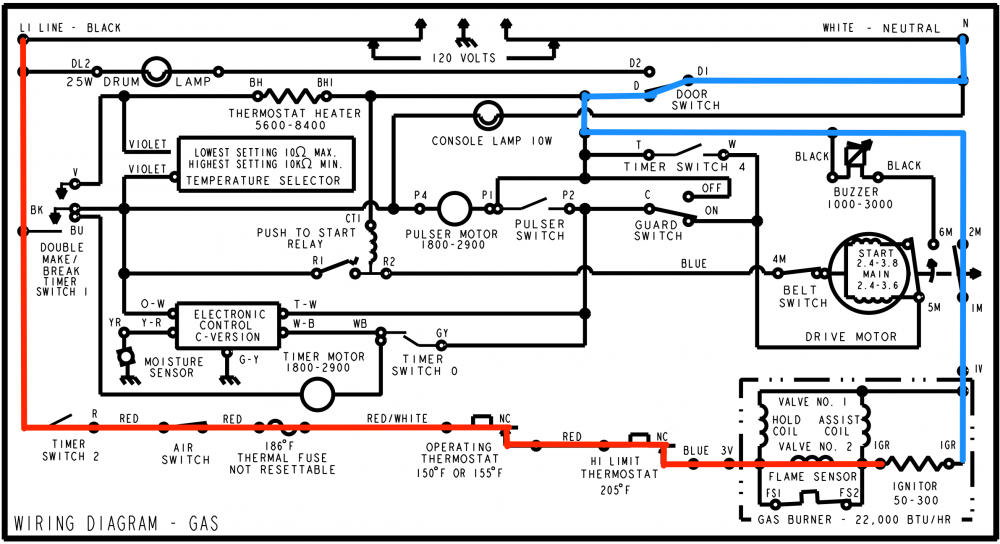

Here's what the ignitor's circuit looks like with the dryer running. We've got line and neutral all the way up to the ignitor, meaning that when we put our voltmeter leads across the ignitor, we read 120 volts. Our voltage supply is good. The only explanation for why the ignitor isn't running is that it has gone electrically open.

But wait -- we confirmed that it wasn't open with our ohms measurement. How could it be open now?

Let's step through what's going on in this circuit the instant that power is applied to that ignitor.

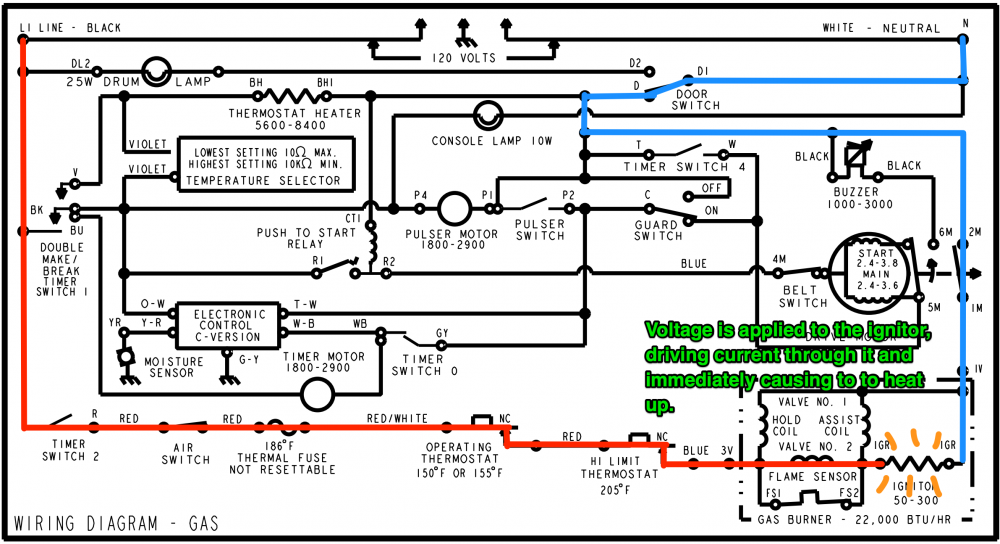

As soon as there's a voltage difference across that ignitor, electrons get blasted through it. This causes it to heat up -- and that's exactly what's supposed to happen.

But in our particular case...

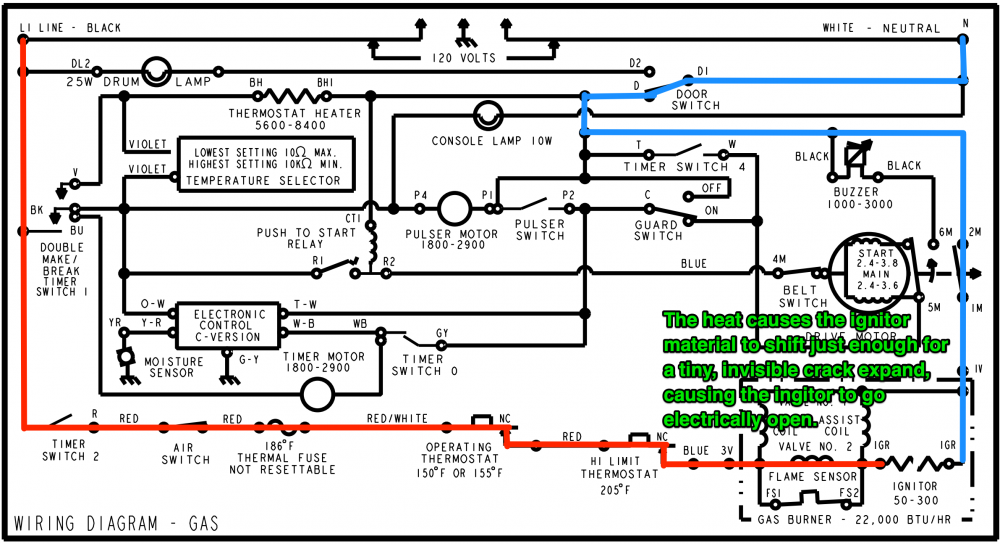

And here we have the solution to our quandary: failing under load.

In its simplest form, this is exactly what failing under load looks like: thermal expansion due to the heat from current flow causes a tiny break to become an electrical open. Nothing more complicated than that.

This is not some whacky, once-in-a-blue-moon scenario. Failing under load happens all the time in various appliances. And it's precisely because of this that we say ohms lie. We went through and did an ohms test on every single component in the circuit and got no information out of it. And all we needed to do was take a single voltage measurement on a live circuit to tell us what was wrong.

Does this mean that you should never, ever do an ohms measurement? Of course not. There are some situations that will call for an ohms measurement, but it's up to you as the thinking technician to know when those situations are and how to interpret the results of the test.

"Ohms lie" is a pithy shortening of this whole concept, and I think a lot of techs who hear it don't know exactly what we mean when we say it. When we say, "Ohms lie," what we mean is, "An ohms measurement is one of the least informative tests you can do, and there's almost always a more useful test you can do instead."

But that takes a lot of breath, so instead we just say: ohms lie.

Want to learn more about how to properly make electrical tests and troubleshoot like a pro? Click here to check out the online Core Appliance Repair Training course over at the Master Samurai Tech Academy.

-

.png) 7

7

-

1

1

15 Comments

Recommended Comments