An Introduction to R600a and Lokring

We’ve all been hearing about R600a refrigerant for years now, and the reality is that it’s no longer an innovation in the area of household refrigeration; it’s the new standard.

With the majority of new refrigerators now being R600a models, repair companies need to be ready to perform sealed system repairs on them. This raises a few questions for these companies: how is R600a different from R134a, and what do I need to service R600a refrigerators?

R600a (let's just call it R600 from here on out) is a chemical called isobutane with properties that make it desirable as a refrigerant. Refrigerators that run on R600 still work in the same way that R134a refrigerators do – we’re not reinventing refrigeration here. But R600 systems do have different specifications compared to R134a ones, since R600 has different properties (boiling point, etc.).

The big reason why we have new techniques and tools for servicing R600 is because this refrigerant is flammable. As you might have gathered from its chemical name, R600 is an isomer of butane, very similar to what you might find in a lighter. For this reason, the old tried-and-true method of sealed system repair involving brazing is no longer considered safe by some manufacturers.

Now, there’s some debate as to how unsafe it really is – after all, a typical R600 sealed system contains less than a BIC lighter’s worth of butane spread throughout dozens of feet of tubing. In fact, manufacturer opinion is evolving, and some of them are now allowing brazing as an option provided certain procedures are followed.

But for those that don’t want to worry about extra precautions when brazing, that’s where Lokring comes in. Lokring is a set of tools and fittings that allows for sealed system repairs without any need for brazing. It does this by using special pressure fittings which, when properly installed, create completely airtight seals.

Let’s walk through the different Lokring components you need to do R600 sealed system work. Note that these are in addition to the standard tools needed for any sealed system work (vacuum pump, recovery bags, gauge manifold, etc.).

Tubing cutter

This is one of the most inexpensive parts of the tool list, but essential for getting the job done right. In order to ensure a hermetic seal with your Lokring connectors, you need clean cuts on the tubing, with no crimping or deformation. I recommend a compact cutter, like the one pictured above. Depending on the job, you sometimes have to make repairs in really cramped corners of the machine, so a bulky tool will just get in the way.

Lokprep

Lokprep is an anaerobic sealant (not an adhesive) that fills the tiny gaps between the tubing and the Lokring fittings. It must be evenly and completely applied to both tubing ends before they are inserted into the fitting for a proper seal.

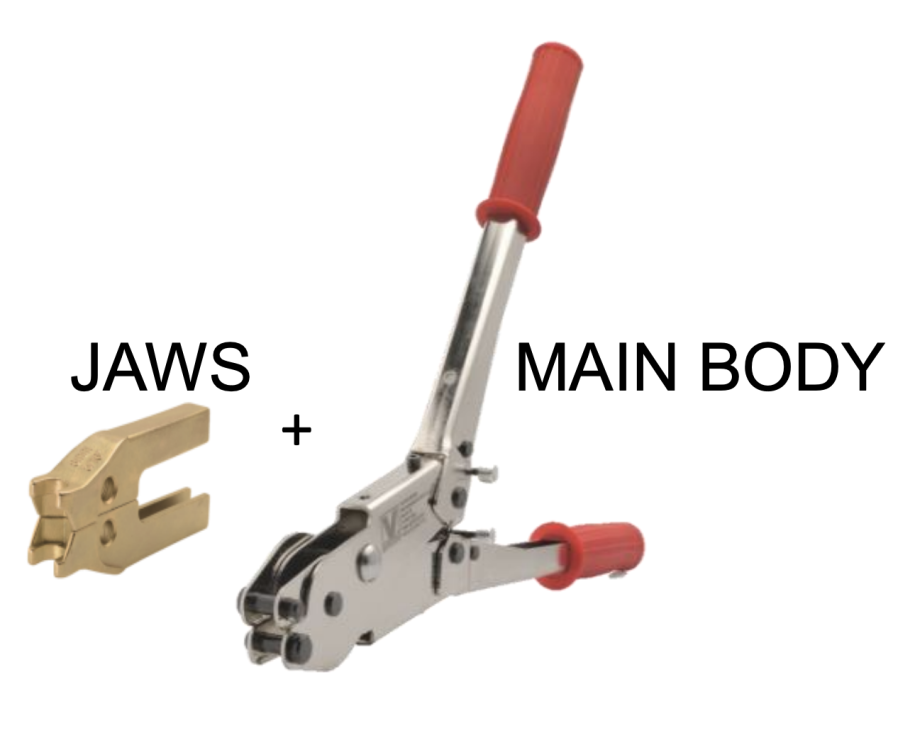

Lokring Assembly Tool

Here are the famous Lokring clamps. This is the tool that the tech uses to squeeze Lokring connectors into place, locking the two pieces of tubing together and, if done correctly, creating a perfect seal.

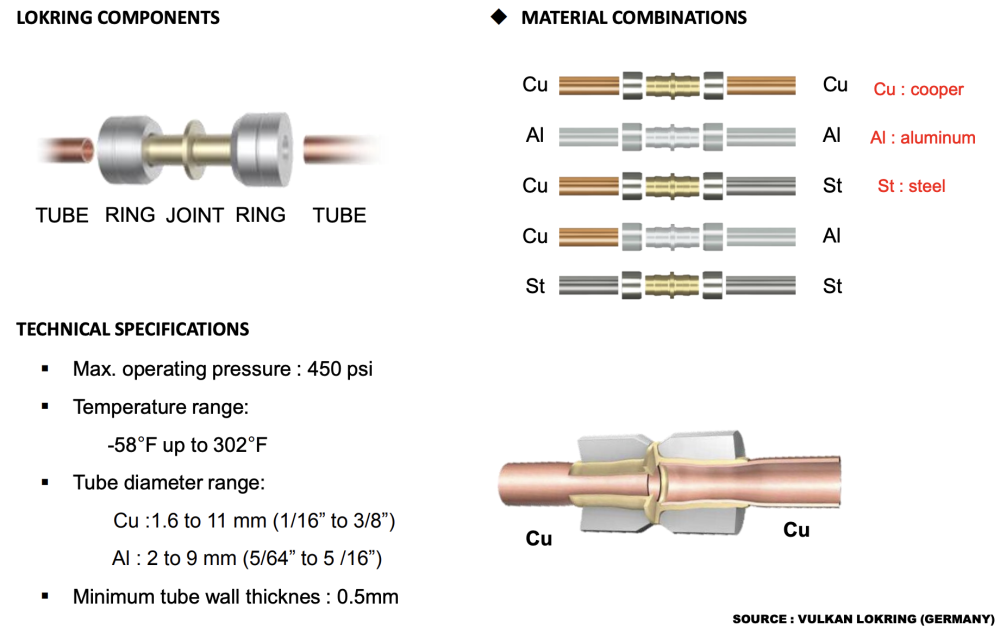

Lokring connectors

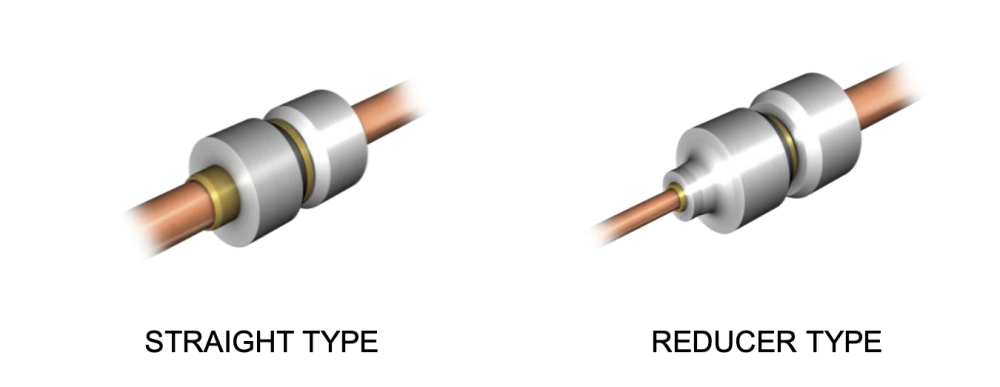

Lastly, the connectors themselves. These are where the investment (and some of the headache) of Lokring comes in. In order to be properly prepared for the various kinds of sealed system repairs he could encounter, a tech needs to be stocked with a wide variety of fittings.

Sealed system tubing varies from 2mm to 11mm in diameter throughout the refrigerator, and the connector needs to match the diameter of the tubing. When the tubes that need to be joined are of different diameters, you need a reducer-type connector that’s properly sized for both.

In addition to diameter, material has to be taken into consideration. The standard brass connectors can’t be used to join aluminum tubing due to galvanic corrosion, so any connections that involve aluminum must use an aluminum connector. Aluminum tubing is usually found around the evaporator, while elsewhere in the refrigerator (such as the machine compartment) will generally have copper tubing.

The upshot of these different connector sizes and materials is this: first getting into Lokring will be an investment. Each individual connector costs between $5-12, and with how many a tech needs to have on hand, that can add up. A typical Lokring starter kit can easily cost upwards of $1,000.

Don’t let that spook you, though. Sealed system work, when done intelligently, can have huge profit margins. In the end, you need to make the call on whether R600 servicing is right for your business – and hopefully this article helps you do that!

Wondering where to buy Lokring? Vulkan, the company that develops and produces Lokring, does not distribute its products itself. So if you’re looking to purchase some Lokring kits, you would want to turn to your preferred appliance parts distributor.

Want to train techs who will be prepared for anything they encounter in the field? Click here to check out our online, in-depth appliance repair training courses at Master Samurai Tech.

-

.png) 11

11

-

1

1

49 Comments

Recommended Comments