How Many Speeds Does This Fan Motor Have?

Let's look at a seemingly simple load that has more going on than you would think: a multi-speed hood fan in a microwave. The questions we want to answer are: how many speeds does this fan have and how does it achieve those speeds?

If you look at the spec block for the motor, the answer to the first question seems easy -- looks like it's a simple two-speed motor.

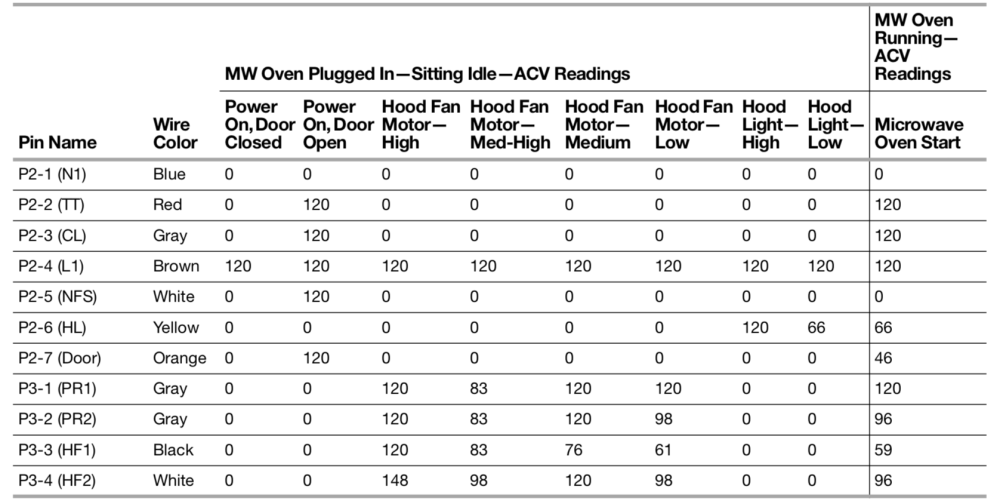

But when you look elsewhere in the tech sheet, you find this voltage table that seems to state you have four speeds. (By the way, there are a number of erroneous values in this voltage table, so we're not going to use it as part of our case study -- but if you want extra credit, you can identify the nonsensical values).

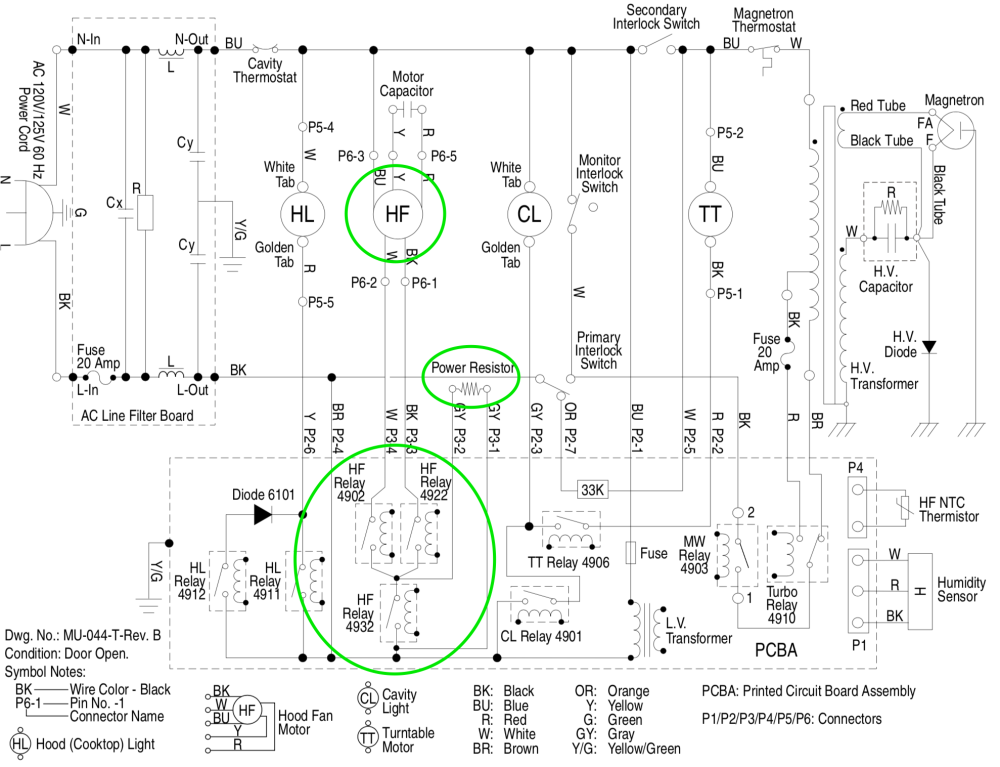

And when you then look at the schematic, you see that you have a number of components in the circuit for the hood fan -- two more relays than you would expect, and a resistor.

Let's cohere all of this information along with our functional understanding of circuits to puzzle out what's going on.

We know that the motor has two different speed windings from the spec block. And we know from the wire colors given there that P6-1 is the pin for the high speed winding, P6-2 for the low speed winding, and P6-3 for common.

We can now look at the schematic again and consider what those relays are doing. Relays 4902 and 4922 are pretty clear: that's how the control selects which motor winding to energize: high or low. But what about Relay 4932?

Well, the only thing Relay 4932 could be doing is shunting the power resistor. So when 4932 is open, the power resistor is in series with the rest of the circuit, but when it's closed, no current flows through the power resistor.

And now we have the full picture of what they're doing: by opening and closing certain ones of those three relays below the fan motor, the control can control not only which speed winding gets power, but whether that winding is receiving a full 120 VAC or not.

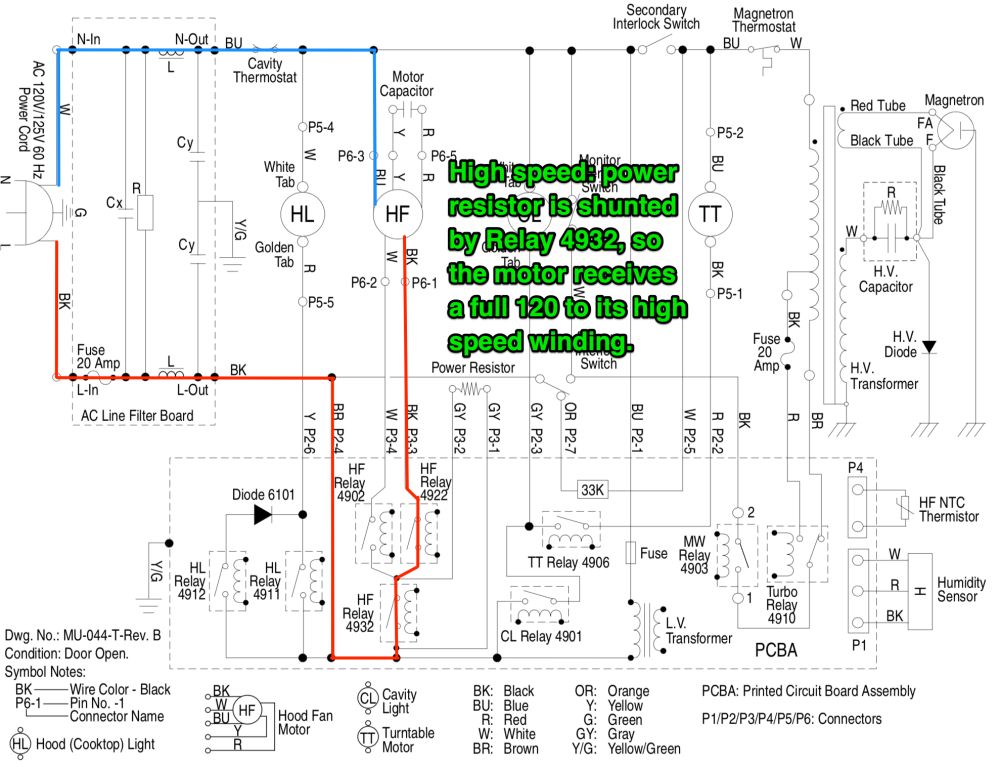

To demonstrate, here's a markup of high speed:

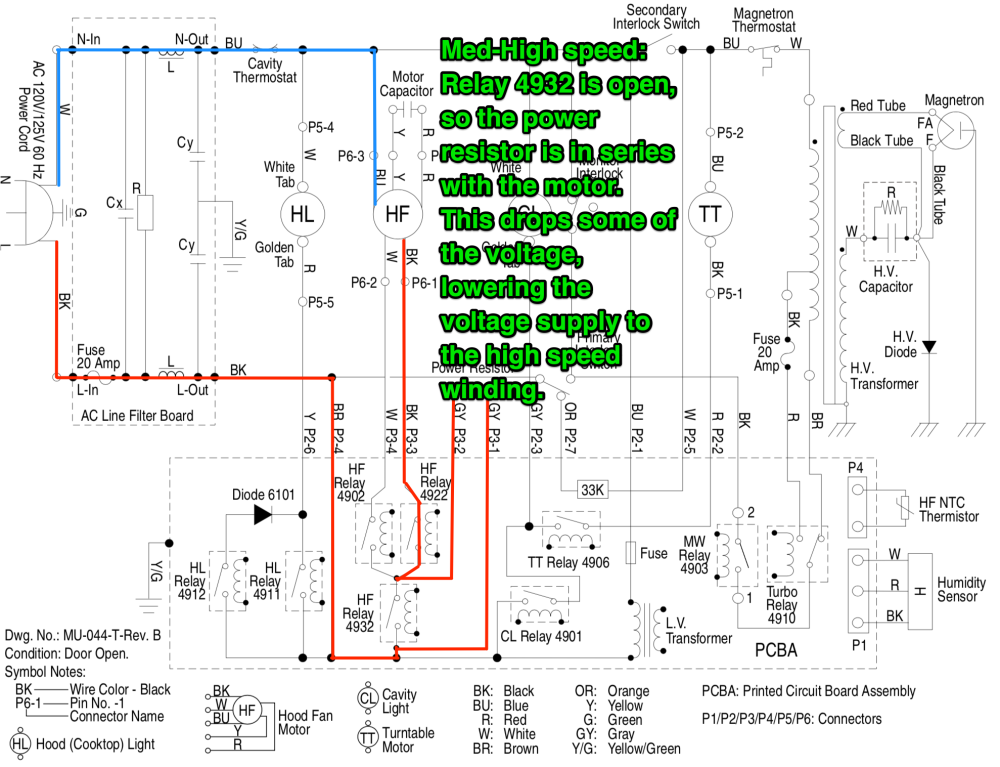

And now medium-high speed:

You can figure out the other two speeds for yourself: medium speed would be the low winding with the full voltage supply, and low speed would be the low winding in series with the power resistor.

And that's it: a low-tech way of achieving semi-variable speed in a fan motor. In a higher-end model, you would just have a variable-speed BLDC motor with infinitely variable speed. But I'm sure the engineers who had to shave down the production cost of these microwaves are proud of themselves for coming up with this little configuration.

Want to learn to decipher schematics like a real tech? Click here to check out our Core Appliance Repair Training course over at the Master Samurai Tech Academy.

-

.png) 3

3

-

1

1

.png.62a7d7300de75dfbd19764a318766630.png)

11 Comments

Recommended Comments