WPL Ceiling Mount IM hack

I’ve seen lots of the WPL build units with the ice maker in the ceiling that get a condition where the fill tube freezes up. I’ve been working on a repair for this and I think I have it dialed in.

Before starting, go through the manual and perform the diagnostic steps as outlined by Whirlpool. But what I’ve been finding in some cases is that the components are working properly- including the fill tube heater, but there was a poor installation job done at the factory, and the heater is making little contact with the fill tube itself. Easy enough fix!

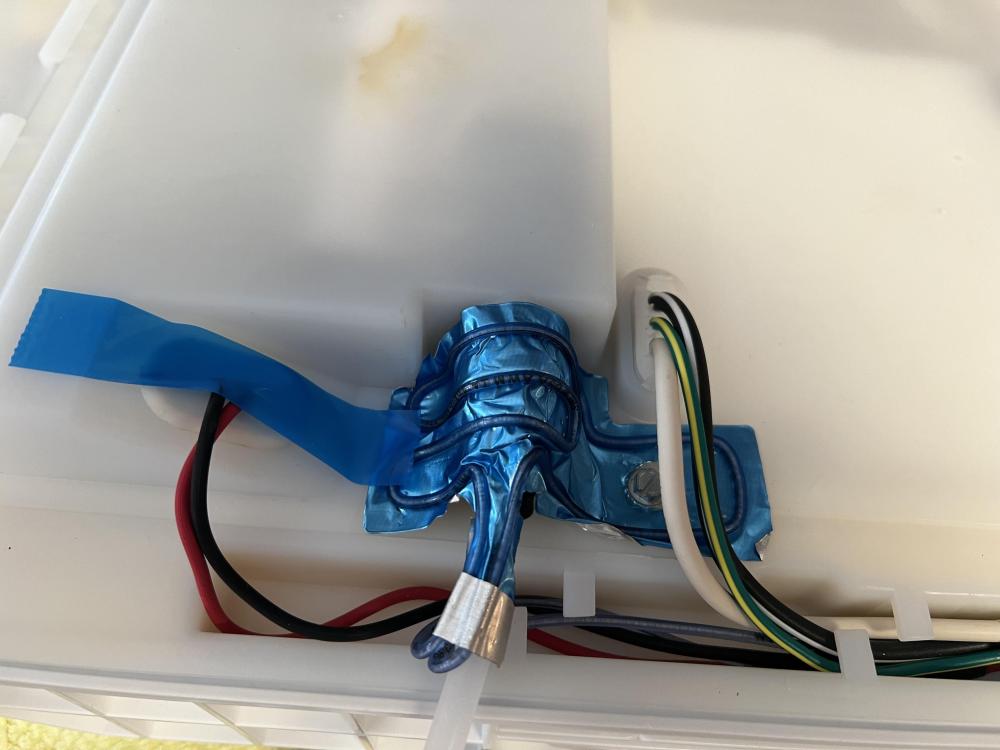

Poorly installed fill tube heater.

Look at the void! Hardly any of the heater is touching the fill tube!

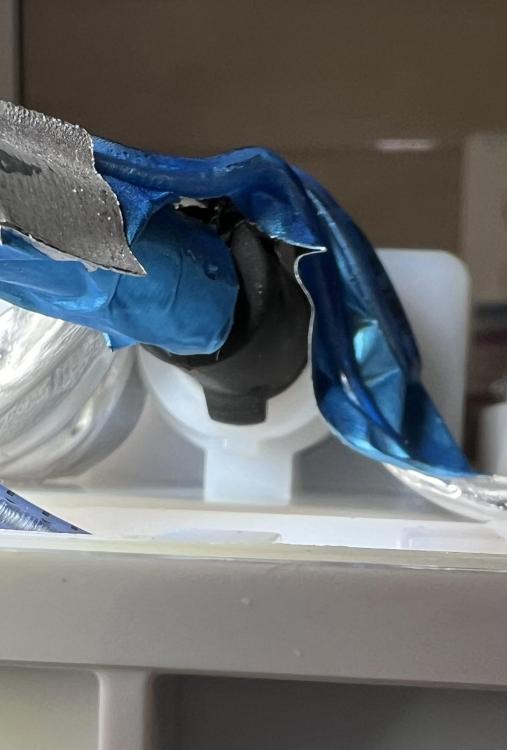

Peel that sucker off. Start reattaching from under the tube.

Now wrap it tightly around the tube.

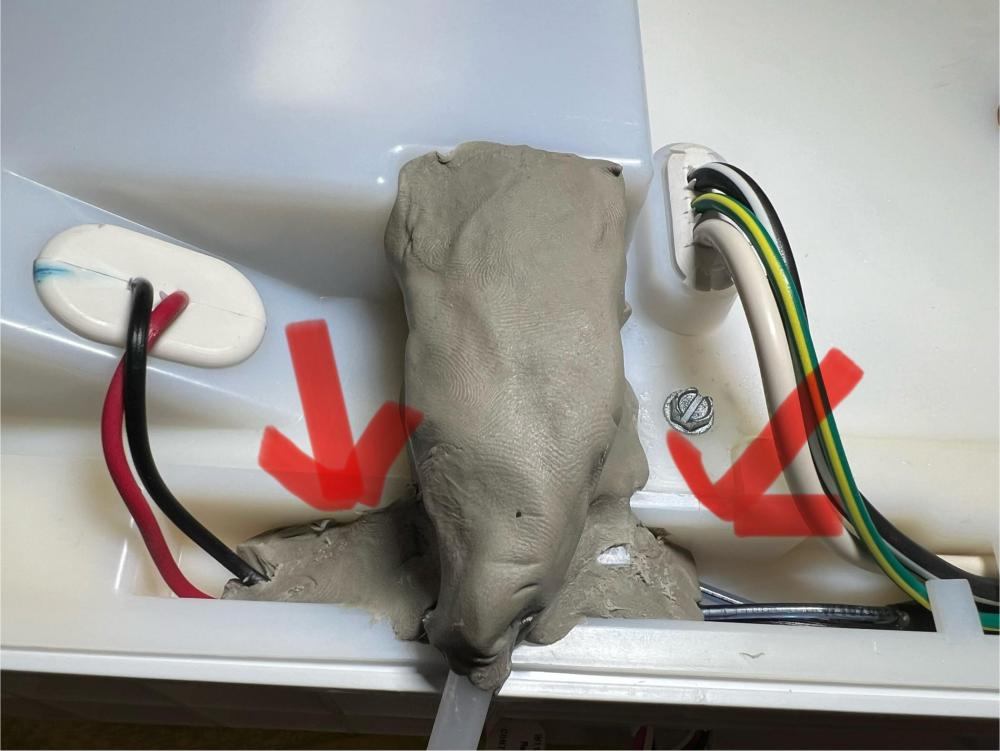

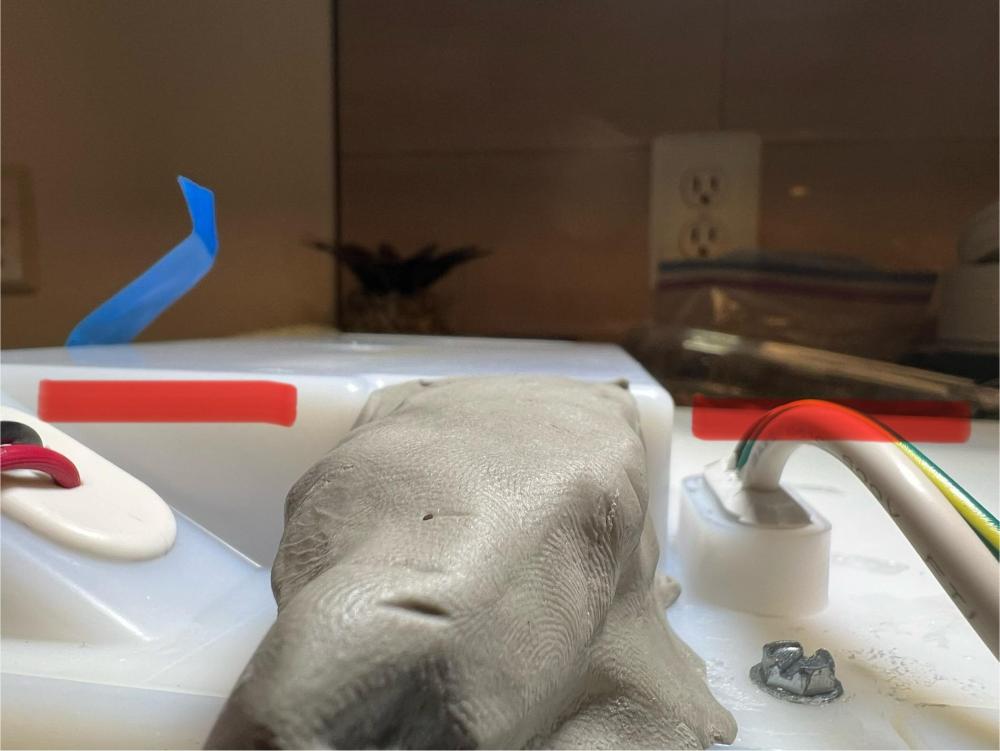

Add some aluminum tape for good measure. Then layer it with thermal putty. Be sure to fill the voids of the wires. And also be sure the putty is flat with the housing so it will fit flush when reinstalled.

Add some aluminum tape to cover the putty so it won’t be messy.

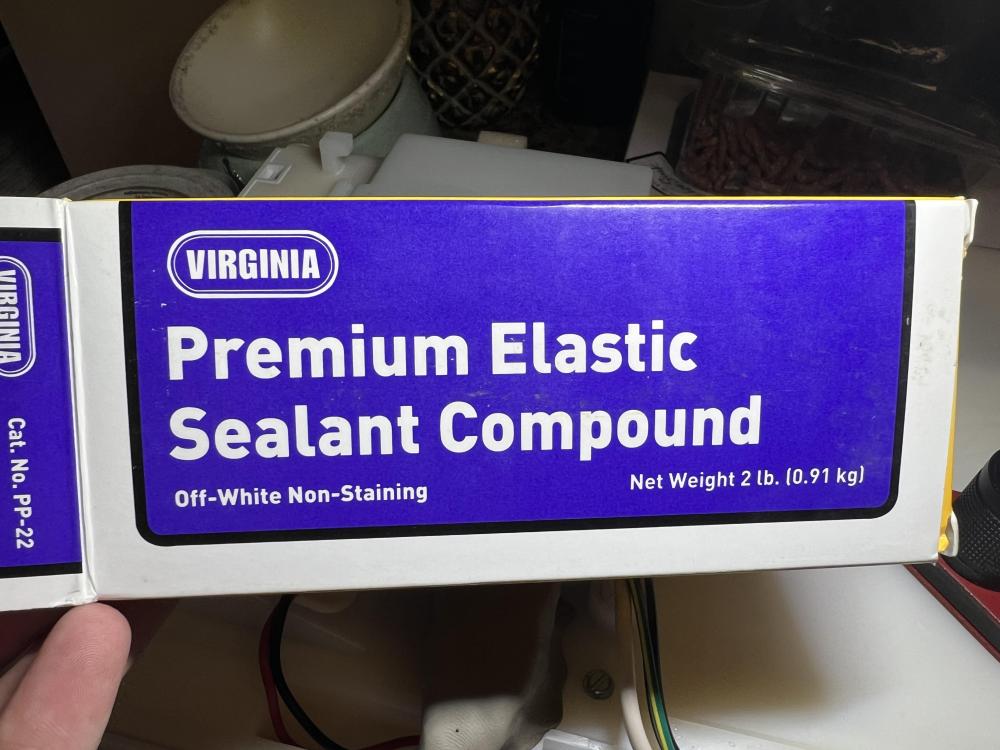

Here’s what I use.

Bonus tip: use a thin wall nut driver for those stubborn recessed screws. A cheap one works great!

-

.png) 10

10

-

5

5

.png.9012a87f3d9d47f1728530e9414b5964.png)

13 Comments

Recommended Comments