Here's What Loading Down Looks Like and How to Troubleshoot It

Most of you have probably heard about loading down before -- when one failed DC component causes a ripple effect that keeps other DC components from functioning properly until the failed component is removed. But what does that actually look like in practice? And how do you go about troubleshooting it?

To answer these questions, let's take a look at a straightforward, real-world example of loading down (taken straight from this topic at Appliantology).

@marshall450 ran into what seemed like a tricky, complex issue with a Whirlpool dishwasher. To quote his problem statement:

QuoteRuns for an hour then circulation pump repeatedly turns on and off and stays in this mode till you turn it off. Overfull and water leaked from the door. Has not been drying dishes.

And it only got weirder once he got to troubleshooting:

QuoteI ran service diagnostics and pulled up 4 codes. 3-2 (turbidity sensor) 6-6 (water cold) 6-4 Unit to full of water) 8-1 (slow drain). After the codes the unit goes through a couple of checks, flashes a couple of lights and then starts to fill. Fill runs for about one second and then the unit shuts off completely.

4 different error codes and strange, erratic behavior from the control? What do you do in a situation like this? How can you possibly approach troubleshooting this without relying upon complete guesswork?

If you know about loading down and how it works, then situations like this become much less mysterious. A main control that is being loaded down by a faulty DC component can behave in unpredictable ways, but the way you can tell if it's being loaded down remains the same. You must simply identify any DC components connected to the main control and then disconnect them one by one. Every time you disconnect a component, you run a test to see if normal operation has been restored to the other functions of the appliance. If they are, you have found your problem component. If not, you move onto the next one.

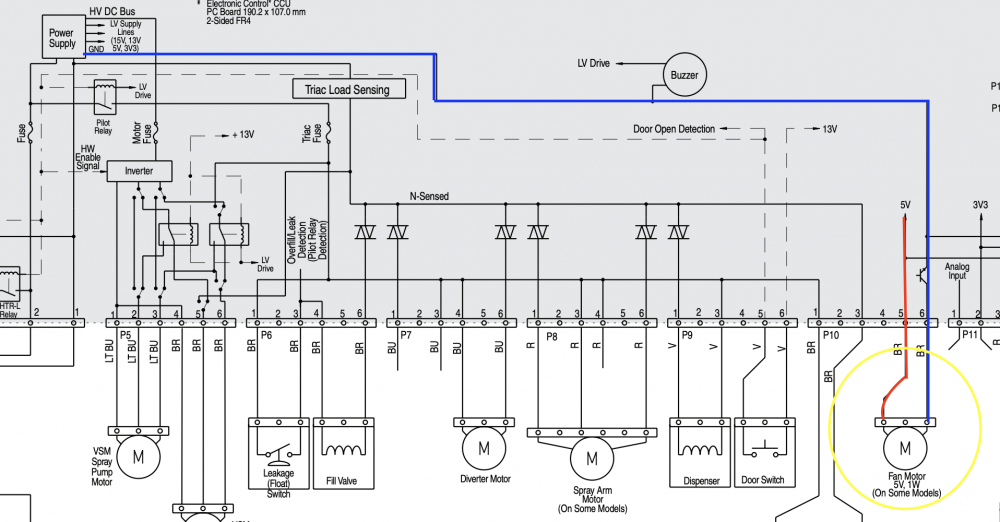

It's a pretty simple process of elimination -- though it can be a bit more involved in units that have sub-control boards. Fortunately, our Whirlpool dishwasher in this example is very straightforward. Take a look:

There aren't many DC components in this unit, as you can see. And only one real DC load -- that 5VDC fan motor circled in yellow. That's an easy, obvious place to begin, and it's your most likely suspect.

And what do you know? As soon as marshall450 disconnected the fan motor from the main control, the erratic behavior stopped. Replace the fan, and problem solved! This is one of many examples of why it's crucial to really understand the technology we're working with as appliance repair technicians.

Want to learn more about loading down? Check out info-packed webinar recording, available only to our premium members.

-

.png) 11

11

.png.62a7d7300de75dfbd19764a318766630.png)

0 Comments

Recommended Comments

There are no comments to display.