Troubleshooting a Whirlpool Dishwasher with a Cheater Cord

Here's the situation: our tech has a Whirlpool dishwasher that does everything normally, except the wash motor simply won't run.

He's done his due diligence and checked for voltage to the motor -- with a LoZ meter, even! -- and what he's finding is puzzling. It looks like the voltage is jumping around from 0 to 120 VAC erratically. What does this mean? Could it be a bad board?

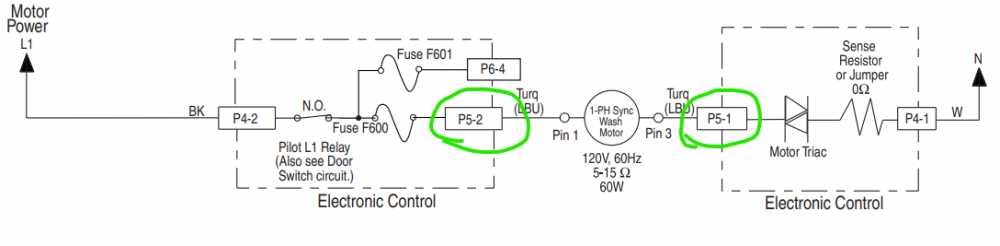

As with all good troubleshoots, let's start with the schematic. Here's just the motor circuit:

Now, I'm going to tell you a dead simple test that will let you immediately narrow in on the problem. It doesn't even require a meter!

All you need is a simple cheater cord. That is, a cord that you can plug into a standard outlet and then connect to your Load of Interest. See those two connector points that I circled? That's the connector that you would disconnect and then plug your cheater cord into.

Does the motor not run at all? Obviously something is the matter with it. Does the motor run completely normally? Problem with the power supply to the motor.

In this particular case, the solution was actually quite interesting. See, the motor ran when connected to a cheater cord, but it sounded off. Our tech took that as the hint that it was, opened up the sump, and cleared out a bunch of gookus around the wash motor shaft. After that, it ran like new. That's a vital clue he never would have gotten without running the motor on a cheater.

So if the board was just fine, what was up with that weird voltage we measured from it?

Brother Bluebird, one of our esteemed Alumni of the Master Samurai Tech appliance repair school, put the final piece in place for what was causing this problem. The board was providing a valid power supply to the motor, but as soon as it did so, it sensed out of spec amps in the motor circuit. Why? Because the blockage in the wash motor was causing locked rotor current in the circuit. The board's programming sensed this amperage as abnormal and shut off power to the motor.

So there you have it -- through clever use of the schematic and one dead simple test, you can get right to the bottom of a seemingly tricky problem. Want to learn more about how to efficiently and effectively use troubleshooting techniques like a pro? Check out this webinar recording we've made on the subject -- available only to premium members.

-

.png) 4

4

3 Comments

Recommended Comments