Can you Check a BLDC Fan Motor with Ohms?

Let's say you're on a call for a Whirlpool GI6FARXXY07 refrigerator. You notice that the evaporator fan isn't running, even when the unit isn't in defrost. "Simple enough," you think, and you disconnect the fan harness and check its resistance.

Wow -- 500 K-ohms! No way that's in spec. Gotta be a bad fan motor, right?

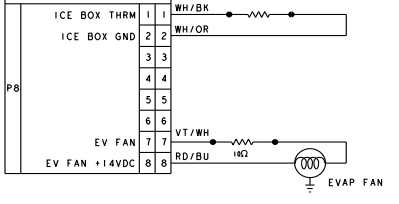

Before we get too hasty, let's step back for a moment and do what we should have done at the start -- look at the schematic. When we do that, we can pretty easily locate the evap fan motor. Here it is:

What you should immediately notice is its power supply of 14 VDC. That low DC voltage should immediately tip you off that there's perhaps a little more to this fan than we thought.

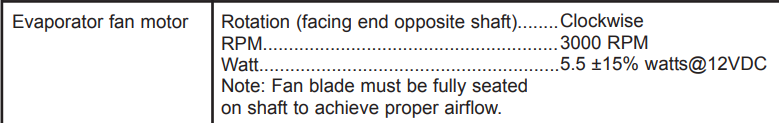

We can investigate further by looking at the specs and then a picture of the physical fan.

Most of you will probably point out now that this is clearly a BLDC fan motor. You can tell from both the low DC voltage spec and from the look of the fan. That's a very typical BLDC fan motor, in case you didn't know.

So what does this mean for our ohms test? Well, something that we all know about BLDC motors is that they require an inverter board to run. We don't see an inverter board on the schematic, but that doesn't matter -- small BLDC motors like this have the inverter board built into the motor casing.

You should now be putting together why we got such a high resistance reading. We weren't just reading the resistance of the motor windings -- we were reading the resistance of the inverter board, too. In other words, it was a nonsensical measurement that didn't tell us anything diagnostically useful.

Instead, what we should have done as soon as we suspected something was wrong with the fan is perform a DC voltage measurement at the board. That would tell us right away if the fan motor was receiving a proper power supply and identify either a problem with the fan itself or a control issue. Ohm measurements have their place, but they are one of the least reliable tests a tech can make, and they must be used judiciously, if at all.

We have a webinar recording that goes into detail about these BLDC fan motors. You can check it out by clicking below-- viewable only by premium members.

-

.png) 3

3

-

1

1

.png.9012a87f3d9d47f1728530e9414b5964.png)

3 Comments

Recommended Comments