Testing for a Failed Timer with EEPs and Convenient Voltage Tests

Our scenario today is a dryer that heats intermittently. Blitzing through the Ten-Step Tango, we select the heating element as our LOI.

But how do we test the heater's power supply? Do we have to start tearing things apart to do our tests?

If you've been around Appliantology long enough or taken our courses over at Master Samurai Tech, then you'll know that the answer is, of course, "no". Instead, we've just got to look at the schematic and pick some clever test points.

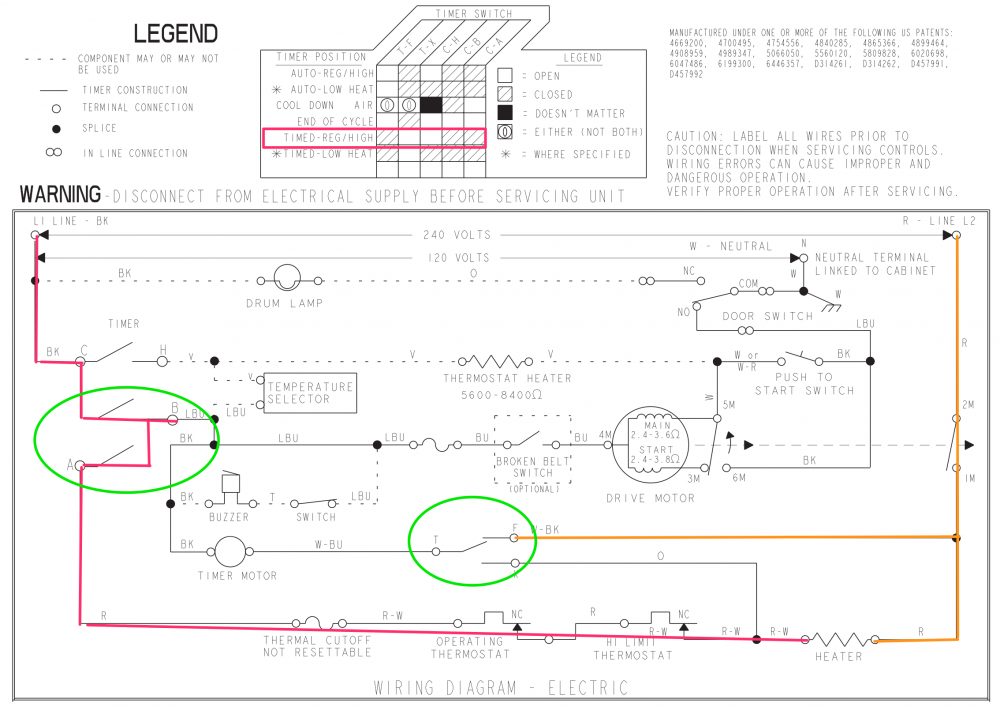

All we need are two tests. The first from from contacts A to B. This is just to see if that timer contact is closing properly. With the heater running, you should read 0 VAC. if you read 240 VAC, that's an open timer contact.

The second test would be from contacts C to F. This time, we're confirming the presence of L2 at contact F, thereby also checking if the centrifugal switch is working properly.

Important note: Both of these tests need to be made with a loading meter or a meter on the LoZ setting. Otherwise, your readings might not be reliable.

Both of these tests can be made right from the timer, so there's no wasted time or extra liability from digging into the belly of the beast. And as it turns out, with just these two tests, the tech was able to identify a failed timer contact.

Want to learn how to read schematics and troubleshoot like a real tech? Click here to check out our Core appliance repair training course at the Master Samurai Tech Academy.

-

.png) 7

7

-

1

1

5 Comments

Recommended Comments