FAQs | Repair Videos | Academy | Newsletter | Contact

Search the Community

Showing results for tags 'motor'.

-

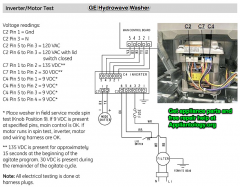

GE Hydrowave Washer Inverter Motor Test

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Washer Repair

Buy GE washer parts with a 365-day return policy here ==> http://www.repairclinic.com/GE-Washing-Machine-Parts -

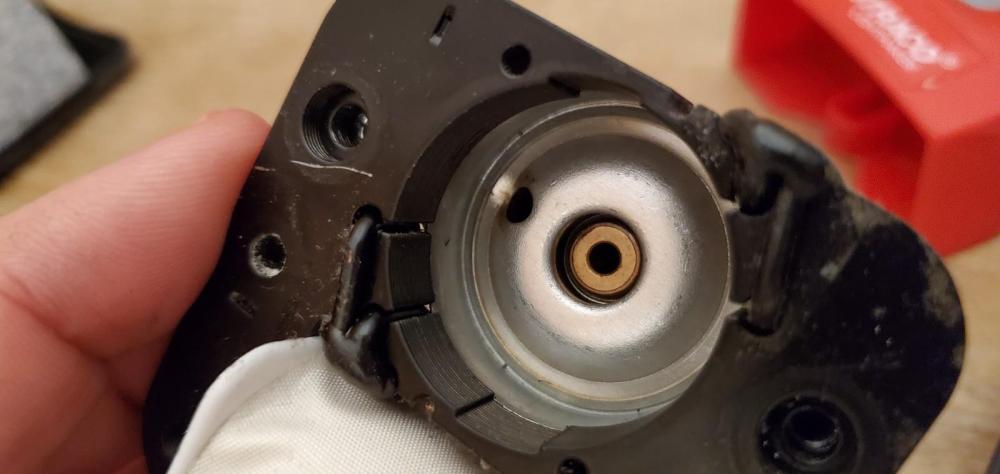

LG 349R refrigerator. Noisy Condenser fan motor4680JB1035H. Can I replace ball bearings?

benyamin39 posted a topic in DIY Appliance Repair Help

Hi. I have a LG refrigerator model 349R. It is in very good condition, the only problem is the condenser fan motor that gets noisy some time. I remove the part and spinned the axis. I heared some squeaking so the problem is the motor. I opened it and here are the pictures. Is there an alternative to replacing the entire motor : 1. Can the ball bearing be removed and replaced? 2. Is there a way to grease it (although I believe those bearing are not meant to be greased) 3. What is the purpose of the hole on the side. I found some sort of gum in it. Thx for your help- 3 replies

-

- refrigerator

- motor

-

(and 2 more)

Tagged with:

-

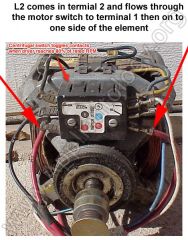

Dryer Motor Centrifugal Switch

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Dryer Repair

Example shown is for a Whirlpool dryer. All dryer motors operate similarly. Some centrifugal switches are separately replaceable (like this one); some are not. For an electric dryer no-heat complaint where you've checked everything else and still not getting heat, that only leaves a bad centrifugal switch in the dryer motor. On most models, that means a new motor. Buy parts for your dryer with a 365-day return policy here ==> http://www.repairclinic.com/Dryer-Parts -

Any Miele experts out there? The drum in my T1415 dryer stopped tumbling. I've opened the dryer up and noticed the smaller v belt had snapped. I ordered a replacement through Miele but it got me thinking.... Since I wasn't able to get the right side panel all the way off (I could use help there too), I didn't really get a good look at the motor. Question, does the motor drive both the drum and the blower fan? Reason I ask is because the blower still works and I want to make sure the v belt just broke due to age vs the motor seizing up and snapping the belt. If motor drives the blower fan, then I only need to replace the belt vs belt plus motor. Apologies for the long winded description. Any insight would be helpful. Thanks in advance.

-

New Appliance Service Manual added: Klixon® Compressor Overload Control Specifications

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

Klixon® Compressor Overload Control Specifications View File Two engineering briefs from Sensata on their Klixon® line of compressor and motor overload controls. (Klixon® is the trade name for the overload protectors and is the most common one used in the industry.) The briefs cover the two most common types of overloads used with single phase compressors and motors: Phenolic 4TM series Submitter Samurai Appliance Repair Man Submitted 09/11/2017 Category Appliance Repair Manual Pot Luck Supper -

Klixon® Compressor Overload Control Specifications

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

Version 1.0.0

118 downloads

Two engineering briefs from Sensata on their Klixon® line of compressor and motor overload controls. (Klixon® is the trade name for the overload protectors and is the most common one used in the industry.) The briefs cover the two most common types of overloads used with single phase compressors and motors: Phenolic 4TM series -

DRYER HUMS-Won'T START- WGD9600TW1 -Whirlpool--7 years old

alexakos posted a topic in DIY Appliance Repair Help

Hi. I'm very much an amateur but the dryer is all taken apart now, so there's no going back!When Start is pressed, you hear a hum and drum doesn't turn, and the dryer doesn't go on. So I suspected the motor. At first I swear I saw a PF code briefly. Some people online say the thermistor can cause that error code although I'm not sure why that would be. When I went to diagnostic mode it said F01, which means control board apparently. I did the diagnostics per the tech sheet. The power to the motor on the control board was ok.The thermal fuse was ok.The thermistor had a reading of 16 ohms with a room temp of about 69, which according to the chart I saw means it's bad. It should be 10. It should be 16 at 60 degrees.Per the tech sheet I checked the resistance on the motor and I got a reading of 0 on all three tests: main winding, start winding, and belt switch. Tech sheet says the readings should be somewhere between 3.3-3.6 (main), 2.7-3.0 (start), and from infinity to a few ohms as the pulley arm closes the switch. But I get zero on all 3. Am I doing them wrong? Some sites say the motor should be zero. -

This all started with and E3 error code. I replaced the motor with a used motor. Same problem -- but before anybody starts in on me please consider that I live in a remote little village in the jungles of southern Costa Rica. All appliance repair is DIY and parts are nearly impossible to find -- and they cost 3 to 5 times as much as in the States. So with all of this as background let me tell you what I've seen, or rather heard, and maybe somebody on this forum can help me sort it out. The motor won't start which of course ends in an E3. The Hall sensor is evidently working just the way it is supposed to. The drum, while I can hear a wee bit of unpleasantness in the bearings, turns freely. When the motor is trying to start I hear a short chatter, like a chattering relay armature, for about 1 to 1.5 sec. This repeats another 4 times at 2 to 3 sec intervals before it codes out. If I take the belt off it starts every time however. At that time I also hear a very shortened burst of that same chatter begin just as the motor starts up. So I, being profoundly ignorant in these matters have consulted the all-knowing internet and have come to the conclusion that what I am hearing is the DC motor starter. If I understand it correctly, when a DC motor starts up we will see high current flow and low torque. To overcome that little problem requires a starter with some sort of mechanical device that successively switches out (i.e. removes) resistance as the motor begins turning. Now, to bolster this diagnosis I have also noted that the series of clicks that I referred to as "chatter" concludes in a clunk. This is consistent with descriptions I have found of 3 or 4-point starters where the "starter armature" is held in the run position until the motor is switched off, at which time the armature it is returned to the off position by a spring (ka-thunk). When the motor does run I also hear that same clunk just as the motor is switched off, just as I would expect. Finally my used replacement motor also trips the GFCI about 10% of the time just at the instant I would anticipate the "chatter" to start. A failed or failing starter would again seem consistent here. That is, the lack of back EMF results in very high current flow. So extrapolating further, all of this would seem consistent with a failed primary resistance (or primary, secondary and maybe even tertiary) resistance. In other words, the starter armature proceeds through the first couple clicks (remember I hear some shortened "chatter" begin before the motor actually starts -- when it does start that is) so the first current the motor sees would be with less resistance, thus allowing greater current (accounting for the GFCI tripping) but insufficient torque to get the motor moving when under even the slightest load. Now, both of my (well used) motors have the same problem or at least the same symptoms. This gives me pause. On the one hand I wonder -- is the starter such a common failure point that I would expect both old motors to have the same problem? On the other hand, if I was to start looking for failure points I would always start with the mechanical elements first. The question this leaves unanswered is why it would be intermittent. One would think, or at least I would surmise, that such a failure would be a hard failure. Then again, if everything has cooled down the motor just might be able to muster enough torque to get it started, if, if, if....... Finally, I know that "the dots" can always be connected in lots of different ways -- especially by the ignorant. This all seems so right though. CAN ANYBODY CONFIRM MY DIAGNOSIS, GIVE ME SOMETHING ELSE TO HANG MY HAT ON or at least add to the train of logic here before I start tearing into the guts of the motor (at least I have two to play with). I really hate beating my clothes on rocks at the river. Somebody help me please. AND, thank you for sticking it out far enough to read this. cheers, jerry

-

New Appliance Service Manual added: GE WE17X10010 Dryer Motor Universal Wiring Connections Tech Help Doc

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

GE WE17X10010 Dryer Motor Universal Wiring Connections Tech Help Doc View File Part instruction No PUB number Submitter Samurai Appliance Repair Man Submitted 07/14/2016 Category Appliance Repair Manual Pot Luck Supper -

GE WE17X10010 Dryer Motor Universal Wiring Connections Tech Help Doc

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

-

From the album: Puzzles

-

Repairing the DD Motor on Samsung FL Washing Machines

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

Version Evernote enex ZIP

27 downloads

Important: The Ass'y DD motor is longer be available as of June 23, 2014 as a separate part. After June, 23rd, you will only be able to order the individual sub-components of the DD motor (Rotor, Stator, or Hall Sensor). See the illustration below. Refer to GSPN for the Rotor, Stator, or Hall Sensor part numbers for individual washer models. Evernote enex ZIP -

New Appliance Service Manual added: Repairing the DD Motor on Samsung FL Washing Machines

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

File Name: Repairing the DD Motor on Samsung FL Washing Machines File Submitter: Samurai Appliance Repair Man File Submitted: 16 Nov 2014 File Category: Appliance Repair Manual Pot Luck Supper Important: The Ass'y DD motor is longer be available as of June 23, 2014 as a separate part. After June, 23rd, you will only be able to order the individual sub-components of the DD motor (Rotor, Stator, or Hall Sensor). See the illustration below. Refer to GSPN for the Rotor, Stator, or Hall Sensor part numbers for individual washer models. Evernote enex ZIP Click here to download this file -

From the album: appliance pics parts

Pain in the butt to get plastic cover off, tested out at 8 mf is the drive motor LEW005PQ dryer, -

From the album: appliance pics parts

this is the drive belt motor and capacitor, thr blower motor also has a capacitor LEW005PQ dryer, -

Chinese Generic Vs Genuine Whirlpool Replacement Dryer Motor

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Dryer Repair

Buy the genuine OEM replacement motor here: http://www.repairclinic.com/PartDetail/Drive-Motor/279827/2584 -

Basic Motor Function Test for Early Model Maytag Neptune Washers

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

-

New Appliance Service Manual added: Basic Motor Function Test for Early Model Maytag Neptune Washers

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

File Name: Basic Motor Function Test for Early Model Maytag Neptune Washers File Submitter: Samurai Appliance Repair Man File Submitted: 17 Jul 2013 File Category: Appliance Repair Manual Pot Luck Supper Basic Motor Function Test for Early Model Maytag Neptune Washers 16008373-01 Click here to download this file -

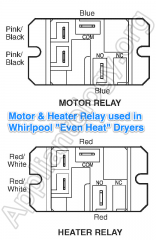

Whirlpool Even Heat Dryer Motor And Heater Relay

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Dryer Repair

These 24vdc relays are used on the Even Heat control boards in some Whirlpool dryer models and are interchangeable. Buy the replacement relay here: http://www.repairclinic.com/PartDetail/Relay/3405281/528722 -

File Name: Whirlpool Dishwasher Service Pointer: TESTING THE GLOBAL WASH SYSTEM (GWS) WASH MOTOR File Submitter: Chat_in_FL File Submitted: 04 May 2013 File Category: Appliance Repair Manual Pot Luck Supper TESTING THE GWS WASH MOTOR Undercounter Dishwasher–Global Wash System Technical Service Pointer #: W10508910 Click here to download this file

File Name: Whirlpool Dishwasher Service Pointer: TESTING THE GLOBAL WASH SYSTEM (GWS) WASH MOTOR File Submitter: Chat_in_FL File Submitted: 04 May 2013 File Category: Appliance Repair Manual Pot Luck Supper TESTING THE GWS WASH MOTOR Undercounter Dishwasher–Global Wash System Technical Service Pointer #: W10508910 Click here to download this file-

- 1

-

.png)

-

- Whirlpool

- dishwasher

-

(and 2 more)

Tagged with:

-

New Appliance Service Manual added: GE Hydrowave Washer Motor Replacement Chart

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

File Name: GE Hydrowave Washer Motor Replacement Chart File Submitter: Samurai Appliance Repair Man File Submitted: 11 Apr 2013 File Category: Appliance Repair Manual Pot Luck Supper HL 02-08 This bulletin is to provide clarification on the motor inverter assemblies for Hydro Wave washer models. Click here to download this file -

GE Hydrowave Washer Motor Replacement Chart

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

-

Whirlpool Dishwasher Wash Motor Failure Analysis, 1 of 5

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Whirlpool Dishwasher Sump Disassembly and Failure Analysis

Photo courtesy of Grand Master appl.tech.29501, a.k.a., Jerry at Elite Appliance Service in Florence, SC. Visit his website ==> http://www.EliteApplianceService.org/ Buy parts for your Whirlpool dishwasher with a 365-day return policy here ==> http://www.repairclinic.com/Whirlpool-Dishwasher-Parts-

- Whirlpool

- dishwasher

-

(and 1 more)

Tagged with:

-

Whirlpool Dishwasher Wash Motor Failure Analysis, 2 of 5

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Whirlpool Dishwasher Sump Disassembly and Failure Analysis

Photo courtesy of Grand Master appl.tech.29501, a.k.a., Jerry at Elite Appliance Service in Florence, SC. Visit his website ==> http://www.EliteApplianceService.org/ Buy parts for your Whirlpool dishwasher with a 365-day return policy here ==> http://www.repairclinic.com/Whirlpool-Dishwasher-Parts-

- Whirlpool

- dishwasher

-

(and 1 more)

Tagged with: