FAQs | Repair Videos | Academy | Newsletter | Contact

Search the Community

Showing results for tags 'troubleshooting'.

-

Samurai's Big Three Troubleshooting Secrets

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

It's tough for appliance techs today. Our biggest competition is from cheap replacement machines. The proliferation of pricey electronic boards in appliances (and their uncertain procurement these days) means that if you can't quickly do a slam-dunk diagnosis, you are at risk of losing customers and your profitability. Meanwhile, electrical troubleshooting is largely a lost science. What exactly have we lost? The Old Skool troubleshooting techniques that us old timers learned way back. And guess what: these same Old Skool troubleshooting skills still apply to modern, computer-controlled appliances! There's a good reason for that: because there is no other way to troubleshoot ANY electrical circuits in appliances. The Big 3 troubleshooting secrets I'm going to talk about in this post are foundational principles that will always apply to any electric circuit, no matter how many control boards the appliance has. If you understand just three things, I guarantee you can successfully troubleshoot ANY appliance electrical problem: The distinction between voltage and voltage drop How loads and switches function in circuits How electrons move around a circuit Let's take 'em one at a time: Voltage vs. Voltage Drop Understanding this distinction is key to correctly interpreting what your volt meter is showing you when you make a measurement. For example, in this video where I showed troubleshooting an inop evap fan in a jazz board refrigerator, the correct diagnosis entirely hinged on whether I understood the voltage measurement on my meter as voltage or voltage drop. Voltage is just the difference in electrical potential between two points. It's called "potential" because voltage creates the potential for electrons to move. Electrons WILL move in response to this voltage difference, always seeking the relatively more positive voltage, IF there is a complete circuit between those two points and the power supply. Voltage is the prime mover in any circuit; it is the first cause for everything else that happens in that circuit. Voltage Drop, on the other hand, is an effect produced when a voltage difference forces electrons through the resistance of a load. The supply voltage is said to be "dropped across the load." If there are loads in series, the supply voltage will drop across each load in direct proportion to the resistance of that load. The sum of the voltage drops will always add up to the voltage supply. Understanding voltage vs. voltage drop is key to making the correct conclusion based on what your meter is showing you and you can almost always avoid unnecessary disassembly and do all your troubleshooting from a convenient location, such as at the timer or control board. Loads and Switches In appliance repair, we are troubleshooting very simple circuits: just loads and switches. "Simple" used here is a technical term. It means that we don't deal with reactive circuits where voltage and current are out of phase with each other. Yes - there's a very deep rabbit hole in electricity that involves reactive components like capacitors and inductors which have complex effects in the imaginary plane (I'm not making this up!) and we need to use the j-operator (also called the i-operator, same thing) to vectorially add the real and imaginary effects to get the total resultant. Fortunately, in the circuits appliance techs troubleshoot, we are only dealing with real voltage and current. That's why the circuits we deal with are called "simple". Even the circuit boards we deal with just function as software-controlled switches for various loads around the appliance with some data communications between boards. The software control doesn't change the fact that a switch is still just a switch and functions the same way in all electric circuits. If you understand how loads and switches each function and work together to do useful work in appliances, you're a third of the way to troubleshooting mastery. How Electrons Move Around a Circuit A long time ago, the movement of electrons was given the unfortunate name "current". I say unfortunate because many techs take this to mean it moves like water. It does not. Electrons have nothing to do with water. Just forget about that whole silly analogy. You need to understand what those electrons actually are and why they move the way they do in a circuit. This is all settled science and, for the types of circuits we work on, electron movement is completely described by simple Ohm's Law equations. Electricity is neither visual (you can't see it) nor intuitive (you can't understand it or predict its behavior by intuition, gut feel, or beliefs). Electrons move in accordance with very specific rules (Ohm's Law) that you need to understand. So you have to spend some time learning the basic principles, which we teach in the Fundamentals of Appliance Repair course at Master Samurai Tech and also in the Webinar recordings here at Appliantology. Your path to mastery If you are motivated and disciplined, you don't even need to enroll in a training course at Master Samurai Tech. If you are a premium tech member here at Appliantology, just make it a habit to watch one webinar recording every weekend and ask me questions if you're confused about something. It's a great deal-- you should take it. Not only do you get tech support and service manuals here at Appliantology, you get in-depth, high quality training taught by someone who knows his stuff like few others in the trade today. However, many of us need (or prefer) a more structured course of training, broken down in more detail, along with quizzes and exams to help keep us accountable. If this is you, then enroll in our courses at the MST Academy (starting with Fundamentals). We are not teaching anything new, or pointy-headed, or academic At Master Samurai Tech and in the many webinar recordings here at Appliantology, I am teaching the same principles of electricity and circuits that technicians have been learning for 50 years or more. Believe it or not, I've had guys try to "agree to disagree" with me about basic electrical concepts, as if it's a political discussion we're having on Facebook. No, we're talking settled science, physics, proven, repeatable, taught the same way all over the world because electricity works the same way all over the world. It will be taught the same way whether you learn it in the Navy, any physics or engineering courses, or at Master Samurai Tech. How do I know this? Because I was trained on basic electricity and aviation electronics in the Navy and then troubleshot computer-controlled radar systems down to the failed component on electronics boards. I also have two engineering degrees, one a Masters, and am a licensed professional engineer in the state of New Hampshire. During my engineering career, I designed hazardous waste remediation systems and industrial ammonia refrigeration systems for large food plants. (If you're one of the morbidly curious, you can read my background here.) So I am not some hack at a keyboard pecking out inane ramblings on a website. I am also not saying this to brag. I didn't discover all this on my own - I know what I know because I had some great teachers and I worked hard to learn what they were teaching because I knew it would help me be more successful. I’ve also spent more than 20 years now helping other techs online, so I know where your pain points are, and I've figured out what you need to know and how to communicate it most effectively to you. If you are a tech who values success, and you want to understand how circuits really work and how to troubleshoot, we teach you the real thing.- 10 comments

-

- 18

-

.png)

-

-

- troubleshooting

- tips

-

(and 2 more)

Tagged with:

-

Non-PCM Repair on a Jazz Board Refrigerator

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

This is a newish Maytag jazz board refrigerator presenting with a warm FF and cold FZ. This was not your typical defrost failure. The failure here was the evaporator fan was not running. I troubleshot the problem without disassembling the freezer-- did it all from the jazz board. Even though this is a modern, computer-controlled refrigerator, what you're about to see are actually old skool troubleshooting techniques that have been largely lost in the appliance repair trade today: reading the schematic and understanding from it how the circuit is supposed to work knowing where to measure with my multimeter properly interpreting my meter readings to draw the correct conclusion about the real problem "jumping the switch" There were no visible failures or burn marks on this board. I had to deduce the cause of the problem from my meter readings and using my jumper wire to prove my conclusions. Come with me now on a journey of Total Appliance Enlightenment... If you can't quite follow or understand what I did in the video, fear not: You can learn how to troubleshoot like this, too! We love teaching electric circuit troubleshooting to people who want to learn this stuff. If you want to earn more money and have greater job satisfaction, enroll now in our Fundamentals of Appliance Repair training course. (PCM - Parts Changing Monkey)- 4 comments

-

- 10

-

.png)

-

-

- troubleshooting

- evap fan inop

-

(and 2 more)

Tagged with:

-

I have an Admiral ATW4475VQ1 top loading washing machine that tries to shake itself apart every time it's in the spin cycle. I've already done a few things to find/fix the issue, but it's still not much better. The things I've tried: 1)making sure the washer is level 2) making sure the laundry load is balanced 3) replacing the 3 suspension springs 4)checking the pads under the drum The machine is level, loads are balanced, and the pads look fine. Replacing the springs helped a little, in that the drum doesn't bang against the sides much anymore, but the whole machine shakes worse than it did. It'll try and walk itself out of its closet if I don't sit on it. I'm not a professional, so I'm not sure what to look for next. Any insight, tutorial links, etc. would be greatly appreciated by me and probably my downstairs neighbors. Cheers!

-

BOSCH Supersilence Serie 4 46db dishwasher - model number SMS46GW01A/01

hilyouare posted a topic in DIY Appliance Repair Help

Hi all, I am not sure what to do about this, but am hoping someone here can offer some direction. We have recently (and finally) gotten a dishwasher, which was gifted to us by a friend (it had been sitting in their garage unused.) It is a Bosch "Serie 4" 46db model number SMS46GW01A/01. There isn't space in any of our small kitchen to put it, so we put it next to the kitchen bench - we had a plumber come and drill some holes, and attach some "extension" hoses to the water intake and outtake to the supplied ones. The dishwasher worked great for two weeks, and now has developed an issue. It's a BOSCH "Serie 4" 46db, with the model number SMS46GW01A/01. While working initially, it now seems to run for a short while (10 minutes?) on any of the washing programs, and then stop with the "Check Water" error lit. We've cleaned all the filters, but it looks like it is obtaining water (at least for a while) as the bottom of the dishwasher is full of water when the program stops. Draining also seems to work, as if I start another program, it will drain it all out. Our guess - Is this likely low water pressure due to the length of the hose, that may have been borderline when it worked and now has dipped for some reason? Perhaps it only needs low pressure in the first phase, but demands more in the later one? Or perhaps some sort of blockage in the water intake or the wastewater pump?. Should we: 1) call a plumber 2) call a bosch technician 3) is there something we can do ourselves? Thanks in advance. Hilary and Richard.- 5 replies

-

- dishwasher

- bosch

-

(and 7 more)

Tagged with:

-

I search service manual please

Electrotech Laval posted a topic in Appliance Service Manual Requests Forum

Manufacturer: LG Type of Appliance: Range Model Number: LRE6323SW Have you validated the model number at an online parts site like Repair Clinic? (yes or no): yes Have you watched the video on how to search for manuals and have you searched the Downloads section prior to posting this request? (yes or no): yes HI, i need service manual for LG Range model: LRE6323SW -

Secrets of the Ten-Step Tango™ Troubleshooting Method Revealed!

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

I've been working with appliance techs online for over 20 years. One of the biggest changes I've seen in the tech community during that time is a steady decline in competence in troubleshooting electrical circuits. It's to the point today that many techs don't even know what real troubleshooting is or looks like. A common misunderstanding is that pattern recognition and parts changing are what constitute "troubleshooting." Real troubleshooting starts with a succinct problem statement that answers one or both of these questions: 1) What is the appliance doing that it should NOT be doing? 2) What is the appliance NOT doing that it SHOULD be doing? Using the problem statement and the schematic, a skilled technician will identify the load of interest (LOI), analyze the LOI power supply circuit, and then proceed to kick some appliance ass. I've codified this analytical troubleshooting technique into the Ten-Step Tango™ Troubleshooting Method. I've posted multiple webinar recordings demonstrating the Ten-Step Tango™ on various appliances, from simple to complex, from wall ovens to refrigerators and everything in between. Today, I want to call your attention to just three of these. In these three enlightening webinar recordings at Appliantology, each about an hour and a half long, the Samurai unveils the secrets of his own troubleshooting technique: The Ten-Step Tango™. In ten clear, easy to follow steps, you'll learn how to apply this structured troubleshooting procedure to diagnose ANY electrical problem, whether it's an appliance, home solar power system, or anything else electrical. And you'll troubleshoot it with precision and competence. No more guessing and hoping to get lucky. If you're a premium tech member at Appliantology (Professional Appliantologist, Appliantology Fellow, or Master Samurai Tech Alumnus), you can watch these webinar recordings at Appliantology on-demand, 24/7. Access to videos like these are one of the many perks of a Professional Appliantologist membership at Appliantology. You can become one today by clicking here. Reminder: Students and Alumni of the Master Samurai Tech Academy are eligible for a FREE premium tech membership at Appliantology-- see this page for more info. This first video walks you through the Ten-Step Tango™, then shows how to apply it by working through several scenarios based on real-life service calls. This next video gets into some more advanced troubleshooting kata with even more exercises. If you hadn't quite gotten the hang of the Ten-Step Tango™ in the last video, this one will really lock it in for you. Without a solid troubleshooting plan and schematic know-how, the refrigerator problems in this video might have made a parts-changing monkey out of you! Luckily, you've got the Ten Step Tango™ on your side. You'll find all three parts of this webinar series here on the webinar recordings index page at Appliantology. Beyond that, there's over 30 different videos -- that's over 40 hours of content -- all covering fundamental appliance troubleshooting and technology. The knowledge in this treasure trove will serve you well, no matter what kinds of appliances you service, because at Master Samurai Tech, we teach the fundamental technologies that are common to all appliances. Learn more, earn more.- 1 comment

-

- 1

-

.png)

-

- troubleshooting

- ten step tango

-

(and 1 more)

Tagged with:

-

A Day in the Life: A Tale of Two Refrigerator Service Calls

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

In this first video, we troubleshoot a warm beer compartment (fresh food) in a Frigidaire Gallery french door bottom mount refrigerator. The video illustrates the importance of following a cardinal rule of troubleshooting: Fix the obvious problem first. In this case, the customer simply reported that the FF compartment was warm but the freezer compartment was good. We verified these temperatures upon arrival. But then the customer points out that the lights in the FF compartment were stuck on and melted a hole in the liner at the top-- you'll see this in the video. So, in keeping with step one of the Ten Step Tango™ troubleshooting procedure, what is our problem statement? Warm FF compartment? Or... It may have started out that way but now, with this new observation, the problem statement evolves to "lights in the FF compartment stuck on." We then show how to verify this in diagnostic mode and using the video record function on the your iPhone. Then we show how to use the schematic on the tech sheet to deduce the cause of the problem. BTW, we had already tested the door switch in diagnostic mode and it was correctly reporting the open/closed status to the UI so we ruled that out. This case study reveals how imperative it is for the sharp shooter tech to avoid getting tunnel vision based on the customer problem statement and to look for and respond to realtime observations at the service call. In this next video, we take you inside the defective damper assembly in a GE Profile (Arctica series) side by side refrigerator and shows you a common way these dampers fail, allowing too much cold air into the beer compartment. If you want to master the art of refrigerator repair with a high first call complete rate and satisfied customers, then remember to enroll in the Master Samurai Tech Academy's Refrigerator Repair course.- 3 comments

-

- 4

-

.png)

-

- troubleshooting

- frigidaire

-

(and 3 more)

Tagged with:

-

Was Gifted a slightly used, unworking Whirlpool electric dryer. It won't heat up. Replaced all of the common problems. (heating element, upper limit thermo, thermostat control, 2 different fuses, pigtail). Only thing left would be the wiring and the controls. There is evidence of mice living inside the control panel, and one of them chewed thru insulation on one of the timer wires (white-blue). I was able to read continuity from the exposed wire to the terminal. I think I'm on the right track. Any advice? Looks like the only path from the chewed wire would be to ground. Is that enough to short the timer? I don't know how to add individual images from Google photos so here's a link to my Google photos https://photos.app.goo.gl/coLz9wDQjMa4aL8M6

-

No-parts field repairs on two dryers with failed timers

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

I had two service calls recently on two different dryers with the same problem: the motor wouldn't run. These are two different dryers: one an old skool Whirlpool-built unit with the lint filter on the top panel and the other a Maytag Neptune-style dryer. Different disassembly, wiring, and schematics, and completely different timers. But in both cases, the problem was the same--a burnt contact in the timer (failed open so would not close). In the two videos below, I show you how to use the schematic not only to precisely identify the specific failed contact in the timer, but also how to do a field repair to bypass that failed contact and get the dryer safely running again without replacing the timer--all in the first trip. Being able to do these repairs was only possible by understanding how basic electricity and circuits work and by reading the schematics. There is no other way. Well, I guess you could just memorize a bunch of monkey tricks like, "If motor no run on a Maytag Neptune dryer, jumper the yellow and gray wires together." Yeah... good luck with that. What's interesting about these two videos is that the repairs done on each are electrically identical but the physical repair looked entirely different between the two. And that's exactly what you should notice in these two videos. Would you like to be able to troubleshoot like this? You can! These are the kind of skills we teach at the Master Samurai Tech Academy. We're not teaching anything new or pointy-headed, or academic-- these are the skills that most appliance techs used to have 20 years ago but have been largely lost to the trade. That's why you see so many techs out there who don't know how to even begin to troubleshoot an electrical problem and, as a result, the trade is ate up with parts changing monkeys. There is a better way: the Master Samurai Tech way. Start with our Fundamentals course. Don't let the name fool you-- many techs, including those with 20+ years experience do not know what we teach in the Fundamentals course. We know because we've had many students in exactly this situation-- over 20 or even 30 years experience-- take our Fundamentals course and then tell us it was a game changer for them. It can be for you, too. Then, to really kick up your laundry equipment repair skills to 11, take our Washer & Dryer Repair course. You'll be unstumpable! The first video shows the field jumper repair on a Maytag Neptune dryer and the next one is an old skool Whirlpool dryer. Watch and learn.- 12 comments

-

- 4

-

.png)

-

- failed timer

- motor inop

-

(and 5 more)

Tagged with:

-

Samsung Refrigeration Cycle Troubleshooting Guide

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

-

- samsung

- refrigeration

-

(and 1 more)

Tagged with:

-

New Appliance Service Manual added: Samsung Refrigeration Cycle Troubleshooting Guide

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

Samsung Refrigeration Cycle Troubleshooting Guide View File Tech guide for troubleshooting refrigeration system problems: Cycle blockage, Gas Leakage, Comp Locking, PBA defect Submitter Samurai Appliance Repair Man Submitted 09/13/2019 Category Appliance Repair Manual Pot Luck Supper-

- samsung

- refrigeration

-

(and 1 more)

Tagged with:

-

[video] Troubleshooting a Kenmore-Electrolux Dual Fuel Range F30 Error Code

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

This dual fuel range was flashing an F30 error code. The tech sheet says this points to a problem with the RTD (temperature probe). A parts changing monkey reading only the error code description without looking at the schematic replaced the RTD only to have the exact same problem: F30 error code. Watch how a real technician uses both the tech sheet and the schematic to accurately diagnose the problem without guesswork. Get online, on-demand 24/7 appliance repair training on circuits, schematics, technology, and troubleshooting at the Master Samurai Tech Academy, https://mastersamuraitech.com/appliance-repair-courses/- 7 comments

-

- 2

-

.png)

-

- troubleshooting

- f30

-

(and 2 more)

Tagged with:

-

[video] No oven heat on a DUAL FUEL range

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

Watch as I demonstrate some basic troubleshooting katas applicable to all appliances, regardless of brand or type. Wondering what the fault on L2 was? Here's the big reveal: we actually induced the failure ourselves on our test range in the Samurai Studio (in our secret lair hidden deep in a volcano) so we could show you this basic troubleshooting kata. Our videos are not showing pattern recognition ("if this symptom replace this part"), product training, or parts changing. We are showing the high-dollar troubleshooting skills that apply to ALL appliances, regardless of model or type. If this were an actual service call, here would be the rest of our troubleshooting thought process: After narrowing it down to L2 we would check the circuit breaker (turn it off then back on). If still no go on L2, it would be time to pull out the range and check the following: Spades on the plug: evidence of pitting or charring indicates a problem with the outlet. Both 120 and 240 VAC at the outlet. Terminal block: look for burnt wires. Learn to troubleshoot like a Master at https://mastersamuraitech.com/appliance-repair-courses/- 2 comments

-

- 2

-

.png)

-

- no oven heat

- troubleshooting

-

(and 2 more)

Tagged with:

-

How to read the cycle sequence chart on a Whirlpool GWS dishwasher

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

You know that complicated-looking cycle sequence chart on the techsheet for these dishwashers that no one uses because they don't understand it? Yeah, that one. We explained how to use it in the Appliantology Tips and Tricks webinar on August 11, 2019. It really is a powerful troubleshooting aid that lets you check all the functions and loads in the machine in just a few minutes. Appliantology premium tech members may watch the webinar recording here. This webinar recording is one of dozens of other training events on niche technical topics like this that we do at Appliantology-- see the complete list here. If you would like full access to Appliantology which includes all of our original webinar recordings, then become a premium tech member today: https://appliantology.org/store/product/11-professional-appliantologist/-

- 3

-

.png)

-

- troubleshooting

- dishwasher

-

(and 4 more)

Tagged with:

-

Samsung Dryer Troubleshooting and Electric Circuits Review

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

Many techs have trouble interpreting a schematic diagram and understanding how to use it for troubleshooting. In this webinar, held on March 29, 2019, we used a Samsung electric dryer and a GE double oven as case studies to review electric circuit principles and troubleshooting. Some of the topics we talked about: Neutral sensing in Samsung dryers: what that means, what it does, and how it affects troubleshooting Series and parallel circuits and how to identify them on a real-world schematic Voltage in a circuit as a DIFFERENCE in voltage between two points How it can be useful to use a reference other than Neutral for your voltage measurements when troubleshooting; Line can be a reference, too! Properly interpreting your meter reading based on your reference Using the Ten Step Tango to troubleshoot Developing troubleshooting strategies to do all your troubleshooting from the main control board Unique features in Samsung dryers to be aware of when troubleshooting a no-heat complaint. If you couldn't make it, premium tech members at Appliantology can watch the webinar recording here and current Master Samurai Tech students can watch it here. Not an Appliantology tech member? Click here Not a Master Samurai Tech Academy student? Click here-

- 1

-

.png)

-

- circuits

- troubleshooting

- (and 4 more)

-

[Workshop] Voltage & Voltage Drop; Loads & Switches; Jumpers & Cheaters on Saturday, April 13th @10 AM Eastern

Son of Samurai posted an event in Tech Training

untilWho: All tech members at Appliantology: Professional Appliantologists, Senior Appliantology Fellows, Legacy Techs, and Master Samurai Tech Alumni at Appliantology and all students enrolled at the Master Samurai Tech Academy. What: We’re going to talk about some basic electric circuit topics and troubleshooting techniques that many techs are a little shaky on: Voltage vs. voltage drop- commonly misunderstood and misused but understanding the distinction is crucial for accurately troubleshooting AC circuits. Most of the time, we’re troubleshooting circuits composed of loads and switches so if you learn how to troubleshoot just two things- loads and switches- you can troubleshoot virtually any appliance circuit you encounter. Jumper wires and cheater cords- essential components in any troubleshooting arsenal- we’ll look at when, how, and why to use each. Mastering basic concepts like these goes a long way to becoming a competent, consistent troubleshooter. When you have a solid grasp of these foundational concepts, schematics stop being a mystery and become an invaluable diagnostic tool. When: Saturday, April 13th, 2019, at 10:00 AM Eastern Time (adjust your time zone accordingly) Where: All of our web meetings are powered by Join.me. For the connection details, see below. Connection details for Appliantology tech members: (Professional Appliantologists, Senior Appliantology Fellows, Master Samurai Tech Alumni, and Legacy Techs) Click the yellow "Going" button above and then fill out the form on this page to request connection details: Connection details for MST Academy Students: Make sure that you are logged into your account at Master Samurai Tech, then fill out the form on this page to request connection details. How: Download the free Join.me app here: https://www.join.me/apps Here are a couple tips to ensure that the webinars are a smooth, cool experience for you: 1. Arrive early to make sure your connection is working! Also, if you show up late for the webinar, you'll be lost. 2. Watch this ultra-short video on how to use your Join.me control console while you're in the web meeting because you're gonna wanna do cool stuff like: - correctly connect your audio (without producing the dreaded echo!) so you and everyone else can hear what the Samurai is explaining - mute and unmute yourself so we can keep the microphones open and we can all talk- 5 comments

-

- troubleshooting

- workshop

-

(and 3 more)

Tagged with:

-

[Workshop] Electric Circuits Review with Samsung Dryer and GE Oven Case Studies, Friday, March 29 @4:30 PM Eastern

Son of Samurai posted an event in Tech Training

untilWho: All tech members at Appliantology: Professional Appliantologists, Senior Appliantology Fellows, Legacy Techs, and Master Samurai Tech Alumni at Appliantology and all students enrolled at the Master Samurai Tech Academy. What: Many techs have trouble interpreting a schematic diagram and understanding how to use it for troubleshooting. In this webinar, we'll use as case studies a Samsung electric dryer and a GE electric oven with 6 elements and 8 relays. If time permits, we'll review AC voltage difference and how L1 and L2 work together to create a 240 VAC voltage DIFFERENCE (key word there) between two points to make electrons move in the circuit. When: Friday, March 29, 2019, at 4:30 PM Eastern Time (adjust your time zone accordingly) Where: All of our web meetings are powered by Join.me. For the connection details, see below. Connection details for Appliantology tech members: (Professional Appliantologists, Senior Appliantology Fellows, Master Samurai Tech Alumni, and Legacy Techs) Click the yellow "Going" button above and then fill out the form on this page to request connection details: Connection details for MST Academy Students: Make sure that you are logged into your account at Master Samurai Tech, then fill out the form on this page to request connection details. How: Download the free Join.me app here: https://www.join.me/apps Here are a couple tips to ensure that the webinars are a smooth, cool experience for you: 1. Arrive early to make sure your connection is working! Also, if you show up late for the webinar, you'll be lost. 2. Watch this ultra-short video on how to use your Join.me control console while you're in the web meeting because you're gonna wanna do cool stuff like: - correctly connect your audio (without producing the dreaded echo!) so you and everyone else can hear what the Samurai is explaining - mute and unmute yourself so we can keep the microphones open and we can all talk-

- case study

- schematics

-

(and 4 more)

Tagged with:

-

[Workshop] Using Timer Charts and Schematics to Troubleshoot, Sunday, December 9 @3PM ET

Son of Samurai posted an event in Tech Training

untilWho: All tech members at Appliantology: Professional Appliantologists, Senior Appliantology Fellows, Legacy Techs, and Master Samurai Tech Alumni at Appliantology What: Being able to analyze a schematic and see how a circuit is supposed to function is real work that all goes on inside our heads when we're troubleshooting an electrical problem. Even though customers don't see anything happening when we do this, schematic analysis is the indispensable, high skill part of our job as techs. In this workshop, we're going to use the timing chart and schematic on the tech sheet to troubleshoot a no-agitate problem on an old skool Whirlpool direct drive washer. Even techs who have repaired thousands of these machines can get tripped up on this one and start guessing or, worse, blindly changing parts. By using the timing chart and schematic together, we will determine exactly how the motor circuit is supposed to operate. And if you know how a circuit is supposed to work, you can always determine exactly what's wrong in these simple circuits-- no guesswork, no parts changing. We'll use the Ten Step Tango™ Troubleshooting procedure to develop a troubleshooting strategy and working hypothesis along with specific electrical tests to test our hypothesis. When: Sunday, December 9, 2018, at 3PM Eastern Time (adjust your time zone accordingly) Where: All of our web meetings are powered by Join.me. For the connection details, see below. This webinar is open to all Appliantology tech members: Professional Appliantologists, Senior Appliantology Fellows, Master Samurai Tech Alumni, and Legacy Techs. Click the yellow "Going" button above and then fill out the form on this page to request connection details: How: Download the free Join.me app here: https://www.join.me/apps Here are a couple tips to ensure that the webinars are a smooth, cool experience for you: 1. Arrive early to make sure your connection is working! Also, if you show up late for the webinar, you'll be lost. 2. Watch this ultra-short video on how to use your Join.me control console while you're in the web meeting because you're gonna wanna do cool stuff like: - correctly connect your audio (without producing the dreaded echo!) so you and everyone else can hear what the Samurai is explaining - mute and unmute yourself so we can keep the microphones open and we can all talk- 3 comments

-

- 1

-

.png)

-

- webinar

- timing charts

-

(and 4 more)

Tagged with:

-

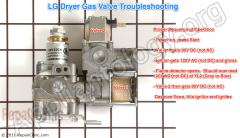

LG Dryer Gas Valve Troubleshooting

Samurai Appliance Repair Man posted a gallery image in The Appliantology Gallery

From the album: Dryer Repair

Replacement gas valve assembly: http://www.repairclinic.com/PartDetail/Gas-Valve-Assembly/5221EL2002A/1266848 -

Speed Queen Alliance Single and Stacked Dryers- Troubleshooting Manual View File Models BDE807*F BDE907*F BDEBEFGS171CN01 BDEBEFGS171CW01 BDEBEFGS171TN01 BDEBEFGS171TW01 BDEBLFGS431AW01 BDET07*F BDG809*F1102 BDG909*F1102 BDGBEFGS111CN01 BDGBEFGS111CW01 BDGBEFGS111TN01 BDGBEFGS111TW01 BDGBLFGS301AW01 BDGT09*F BFEL07*G4018 BFEX07*F BFEX07*F4350 BFEX07*G4018 BFGL09*M3013 BFGX09*F BFGX09*F3060 BFGX09*M3013 BSE807*F BSE907*F BSG809*F BSG909*F FDE807*G3018 FDE807*G4018 GDE807*F5418 GDE807*G3018 GDE907*G3018 GFEG17NG3018 GFEG17NG4018 GFEX17NG3018 GFEX17NG4018 GFEY17NG3018 GFEY17NG4018 GFGG19NM3020 GFGX19NM3020 GFGY19NM3020 HDE007*F HDE007*F1702 HDE007*F3000 HDE007*G3003 HDE007*G3008 HDE007*G3010 HDE007*G4008 HDE007*G4010 HDE107*F HDE107*F1502 HDE107*F1702 HDE107*F3000 HDE107*G3003 HDE107*G3018 HDE107*G4018 HDE507*F1502 HDE507*F1702 HDE707*F1502 HDE707*F1702 HDE807*F1702 HDE907*F HDE907*F1502 HDE907*F1702 HDE907*G3018 HDE907*G4018 HDEB07*J1502 HDEB07*J1702 HDEB07*J99L1 HDEB07*J99L2 HDEF07*J1502 HDEF07*J1702 HDER07*F1502 HDER07*F1702 HDET07*F HDET07*F1500 HDET07*F1502 HDET07*F1702 HDEX07*F1502 HDEX07*F1702 HDEX07*F3000 HDEX07*G3018 HDEY07*F HDEY07*F1500 HDEY07*F1502 HDEY07*F1702 HDEY07*F99N2 HDEZ07*F HDEZ07*F1500 HDEZ07*F1502 HDEZ07*F1702 HDG009*F HDG009*F1102 HDG009*F3000 HDG009*G3008 HDG009*M3008 HDG109*F HDG109*F1102 HDG109*F3000 HDG109*G3013 HDG109*M3013 HDG509*F1102 HDG709*F1102 HDG809*F1102 HDG909*F HDG909*F1102 HDGB09*J1102 HDGB09*J99L1 HDGF09*J1102 HDGR09*F1102 HDGT09*F HDGT09*F1102 HDGX09*F1102 HDGX09*F3000 HDGX09*M3013 HDGY09*F HDGY09*F1102 HDGZ09*F HDGZ09*F1102 HFE167*G4018 HFE507*F1702 HFE707*F1702 HFEB07*J1702 HFEL47*G4018 HFEL67*G4018 HFEX07*F1702 HFEY07*F1502 HFEY07*F1702 HFG509*F1102 HFG709*F1102 HFGX09*F1102 HFGX09*M3013 HFGY09*F1102 HSE117*F HSE117*F2802 HSE117*F2902 HSE517*F2802 HSE517*F2902 HSE717*F2802 HSE717*F2902 HSE917*F HSE917*F2802 HSE917*F2902 HSEB17*J1500 HSEB17*J2802 HSEB17*J2902 HSEB17*J99L1 HSEB17*J99L2 HSEF17*J2802 HSEF17*J2902 HSER17*F2802 HSER17*F2902 HSET17*F HSET17*F1500 HSET17*F2802 HSET17*F2902 HSEX17*F2802 HSEX17*F2902 HSEY17*F HSEY17*F1500 HSEY17*F2802 HSEY17*F2902 HSEY17*F99N2 HSEZ17*F HSEZ17*F1500 HSEZ17*F2802 HSEZ17*F2902 HSG119*F HSG119*F0902 HSG519*F0902 HSG719*F0902 HSG919*F HSG919*F0902 HSGB19*J0902 HSGB19*J99L1 HSGF19*J0902 HSGR19*F0902 HSGT19*F HSGT19*F0902 HSGX19*F0902 HSGY19*F HSGY19*F0902 HSGZ19*F HSGZ19*F0902 JDE807*F JDE807*F4350 JDE807*F5418 JDE807*G3018 JDE907*F JDE907*F4350 JDE907*G3018 JDEBEFGW301EW01 JDEBGFGW301EW01 JDEBGFSW301EN01 JDG809*F JDG809*F3060 JDG809*M3013 JDG809*M3020 JDG909*F JDG909*F3060 JDG909*M3013 JDG909*M3020 JDGBEFGW301EW01 JDGBGFGW301EW01 JDGBGFSW301EN01 JSE807*F JSE807*F4350 JSE907*F JSE907*F4350 JSEBEFGW301EW01 JSEBGFGW301EW01 JSG809*F JSG809*F3060 JSG909*F JSG909*F3060 JSGBEFGW301EW01 JSGBGFGW301EW01 KFEG17NF KFEG17NF1702 KFEG17NG3018 KFEG17NG4018 KFET17NF KFET17NF1702 KFEX17NG3018 KFEX17NG4018 KFEY17NF KFEY17NF1702 KFEY17NG3018 KFEY17NG4018 KFGG19NF KFGG19NF1102 KFGG19NM3020 KFGT19NF KFGT19NF1102 KFGX19NM3020 KFGY19NF KFGY19NF1102 KFGY19NM3020 NDE007*G3018 NDE007*G4018 NDE807*F3022 NDE807*F5422 NDE807*G3018 NDE807*G4018 NDE907*F3022 NDE907*F5422 NDG809*F3022 NDG809*F5422 NDG909*F3022 NDG909*F5422 NFEL47*G4018 NFEL67*G4018 NFEX07*G3018 NFEX07*G4018 NFGL49*M3013 NFGX09*M3013 NSE817*F5422 NSE917*F3022 NSE917*F5422 NSEBXFGW301NW22 NSG919*F3022 NSGBXFGW301NW22 PDE807*G3018 PDE807*G4018 PDG809*M3013 SDE007*F SDE007*F1500 SDE007*F3000 SDE007*F4350 SDE007*G3018 SDE107*F SDE107*F1500 SDE107*F1724 SDE107*F3000 SDE107*F4350 SDE107*F5412 SDE107*F5417 SDE107*F99L6 SDE107*F99L7 SDE107*G3018 SDE107*G4018 SDE307*F SDE307*F1500 SDE407*F SDE407*F1500 SDE407*F3000 SDE407*F4350 SDE507*F SDE507*F1500 SDE607*F SDE607*F1500 SDE707*F SDE707*F1500 SDE807*F SDE807*F1500 SDE807*F3000 SDE807*F4350 SDE907*F SDE907*F1500 SDE907*F1724 SDE907*F3000 SDE907*F4350 SDE907*F5412 SDE907*G3018 SDE907*G4018 SDEA07*J SDEA07*J1500 SDEA07*J3000 SDEA07*J4350 SDEB07*J SDEB07*J1500 SDEBCRGS171TW02 SDEBXRGS171TW02 SDEC07*J SDEF07*J SDEF07*J1500 SDEF07*J4350 SDEH07*J SDEH07*J1500 SDESXRGS171TW02 SDET07*F SDET07*F1500 SDEX07*F SDEX07*F1500 SDEX07*F3000 SDEX07*F4350 SDEX07*G3018 SDEX07*G4018 SDEY07*F SDEY07*F1500 SDEZ07*F SDEZ07*F1500 SDG009*F SDG009*F3000 SDG009*F3058 SDG009*F3060 SDG109*F SDG109*F1124 SDG109*F3058 SDG109*F3060 SDG109*F5412 SDG109*F99L6 SDG109*F99L7 SDG109*G3013 SDG109*M3013 SDG309*F SDG409*F SDG409*F3000 SDG409*F3058 SDG509*F SDG609*F SDG709*F SDG809*F SDG809*F3060 SDG909*F SDG909*F1124 SDG909*F3060 SDG909*F5412 SDG909*M3013 SDGA09*J SDGB09*J SDGBCRGS111TW02 SDGBXRGS111TW02 SDGC09*J SDGF09*J SDGF09*J3060 SDGH09*J SDGSXRGS111TW02 SDGT09*F SDGX09*F SDGX09*F3000 SDGX09*F3060 SDGX09*M3013 SDGY09*F SDGZ09*F SFE107*F SFE407*F SFE507*F SFE507*F1500 SFE707*F SFEA07*G3018 SFEB07*J SFEF07*J SFEL07*G4018 SFEL67*G4018 SFET07*F SFEX07*F SFEX07*F3300 SFEX07*F4350 SFEX07*G3018 SFEX07*G4018 SFEX67*G4018 SFEY07*F SFEY07*G4018 SFEZ07*F SFG109*F SFG409*F SFG509*F SFG709*F SFGB09*J SFGF09*J SFGL09*M3013 SFGT09*F SFGX09*F SFGX09*M3013 SFGY09*F SFGZ09*F SGD109*F3000 SSE007*F SSE007*F1500 SSE007*F3000 SSE007*F4350 SSE007*F99H2 SSE107*F SSE107*F1500 SSE107*F1724 SSE107*F99L6 SSE107*F99L7 SSE107*G3018 SSE117*F SSE117*F1500 SSE117*F3000 SSE117*F4350 SSE117*F5412 SSE117*G3018 SSE307*F SSE307*F1500 SSE417*F SSE417*F3000 SSE417*F4350 SSE507*F SSE507*F1500 SSE517*F SSE517*F1500 SSE607*F SSE617*F SSE707*F SSE717*F SSE807*F SSE807*F1500 SSE807*F3000 SSE807*F4350 SSE807*G3018 SSE907*F SSE907*F1500 SSE907*F1724 SSE907*G3018 SSE917*F SSE917*F3000 SSE917*F4350 SSEA07*G3018 SSEA17*J SSEB07*J SSEB07*J1500 SSEB17*J SSEB17*J1500 SSEC07*J SSEF07*J SSEF17*J SSEF17*J4350 SSEH07*J SSEH07*J1500 SSET07*F SSET07*F1500 SSET17*F SSET17*F1500 SSEX07*F SSEX07*G3018 SSEY07*F SSEY07*F1500 SSEY17*F SSEZ07*F SSEZ07*F1500 SSEZ17*F SSEZ17*F1500 SSG009*F SSG109*F SSG109*F1124 SSG109*F99L6 SSG109*F99L7 SSG109*M3013 SSG119*F SSG119*F3000 SSG119*F3058 SSG119*F3060 SSG119*F5412 SSG119*F5480 SSG119*M3013 SSG309*F SSG419*F SSG419*F3000 SSG419*F3058 SSG509*F SSG519*F SSG609*F SSG619*F SSG709*F SSG719*F SSG809*F SSG909*F SSG909*F1124 SSG909*M3013 SSG919*F SSG919*F3060 SSGA19*J SSGB09*J SSGB19*J SSGC09*J SSGF09*J SSGF19*J SSGF19*J3060 SSGH09*J SSGT09*F SSGT19*F SSGX09*F SSGX09*M3013 SSGX19*F SSGX19*F3060 SSGY09*F SSGY19*F SSGZ09*F SSGZ19*F UDE007*F UDE007*F3000 UDE007*F3025 UDE807*F UDE807*F1702 UDG009*F UDG009*F3000 UDG009*F3025 UDG809*F UDG809*F1102 USE007*F USE017*F5412 USE807*F USG009*F USG019*F5412 PUB 505893R5 January 2016 Submitter Adirondack Bob Submitted 02/16/2018 Category Appliance Repair Manual Pot Luck Supper

Speed Queen Alliance Single and Stacked Dryers- Troubleshooting Manual View File Models BDE807*F BDE907*F BDEBEFGS171CN01 BDEBEFGS171CW01 BDEBEFGS171TN01 BDEBEFGS171TW01 BDEBLFGS431AW01 BDET07*F BDG809*F1102 BDG909*F1102 BDGBEFGS111CN01 BDGBEFGS111CW01 BDGBEFGS111TN01 BDGBEFGS111TW01 BDGBLFGS301AW01 BDGT09*F BFEL07*G4018 BFEX07*F BFEX07*F4350 BFEX07*G4018 BFGL09*M3013 BFGX09*F BFGX09*F3060 BFGX09*M3013 BSE807*F BSE907*F BSG809*F BSG909*F FDE807*G3018 FDE807*G4018 GDE807*F5418 GDE807*G3018 GDE907*G3018 GFEG17NG3018 GFEG17NG4018 GFEX17NG3018 GFEX17NG4018 GFEY17NG3018 GFEY17NG4018 GFGG19NM3020 GFGX19NM3020 GFGY19NM3020 HDE007*F HDE007*F1702 HDE007*F3000 HDE007*G3003 HDE007*G3008 HDE007*G3010 HDE007*G4008 HDE007*G4010 HDE107*F HDE107*F1502 HDE107*F1702 HDE107*F3000 HDE107*G3003 HDE107*G3018 HDE107*G4018 HDE507*F1502 HDE507*F1702 HDE707*F1502 HDE707*F1702 HDE807*F1702 HDE907*F HDE907*F1502 HDE907*F1702 HDE907*G3018 HDE907*G4018 HDEB07*J1502 HDEB07*J1702 HDEB07*J99L1 HDEB07*J99L2 HDEF07*J1502 HDEF07*J1702 HDER07*F1502 HDER07*F1702 HDET07*F HDET07*F1500 HDET07*F1502 HDET07*F1702 HDEX07*F1502 HDEX07*F1702 HDEX07*F3000 HDEX07*G3018 HDEY07*F HDEY07*F1500 HDEY07*F1502 HDEY07*F1702 HDEY07*F99N2 HDEZ07*F HDEZ07*F1500 HDEZ07*F1502 HDEZ07*F1702 HDG009*F HDG009*F1102 HDG009*F3000 HDG009*G3008 HDG009*M3008 HDG109*F HDG109*F1102 HDG109*F3000 HDG109*G3013 HDG109*M3013 HDG509*F1102 HDG709*F1102 HDG809*F1102 HDG909*F HDG909*F1102 HDGB09*J1102 HDGB09*J99L1 HDGF09*J1102 HDGR09*F1102 HDGT09*F HDGT09*F1102 HDGX09*F1102 HDGX09*F3000 HDGX09*M3013 HDGY09*F HDGY09*F1102 HDGZ09*F HDGZ09*F1102 HFE167*G4018 HFE507*F1702 HFE707*F1702 HFEB07*J1702 HFEL47*G4018 HFEL67*G4018 HFEX07*F1702 HFEY07*F1502 HFEY07*F1702 HFG509*F1102 HFG709*F1102 HFGX09*F1102 HFGX09*M3013 HFGY09*F1102 HSE117*F HSE117*F2802 HSE117*F2902 HSE517*F2802 HSE517*F2902 HSE717*F2802 HSE717*F2902 HSE917*F HSE917*F2802 HSE917*F2902 HSEB17*J1500 HSEB17*J2802 HSEB17*J2902 HSEB17*J99L1 HSEB17*J99L2 HSEF17*J2802 HSEF17*J2902 HSER17*F2802 HSER17*F2902 HSET17*F HSET17*F1500 HSET17*F2802 HSET17*F2902 HSEX17*F2802 HSEX17*F2902 HSEY17*F HSEY17*F1500 HSEY17*F2802 HSEY17*F2902 HSEY17*F99N2 HSEZ17*F HSEZ17*F1500 HSEZ17*F2802 HSEZ17*F2902 HSG119*F HSG119*F0902 HSG519*F0902 HSG719*F0902 HSG919*F HSG919*F0902 HSGB19*J0902 HSGB19*J99L1 HSGF19*J0902 HSGR19*F0902 HSGT19*F HSGT19*F0902 HSGX19*F0902 HSGY19*F HSGY19*F0902 HSGZ19*F HSGZ19*F0902 JDE807*F JDE807*F4350 JDE807*F5418 JDE807*G3018 JDE907*F JDE907*F4350 JDE907*G3018 JDEBEFGW301EW01 JDEBGFGW301EW01 JDEBGFSW301EN01 JDG809*F JDG809*F3060 JDG809*M3013 JDG809*M3020 JDG909*F JDG909*F3060 JDG909*M3013 JDG909*M3020 JDGBEFGW301EW01 JDGBGFGW301EW01 JDGBGFSW301EN01 JSE807*F JSE807*F4350 JSE907*F JSE907*F4350 JSEBEFGW301EW01 JSEBGFGW301EW01 JSG809*F JSG809*F3060 JSG909*F JSG909*F3060 JSGBEFGW301EW01 JSGBGFGW301EW01 KFEG17NF KFEG17NF1702 KFEG17NG3018 KFEG17NG4018 KFET17NF KFET17NF1702 KFEX17NG3018 KFEX17NG4018 KFEY17NF KFEY17NF1702 KFEY17NG3018 KFEY17NG4018 KFGG19NF KFGG19NF1102 KFGG19NM3020 KFGT19NF KFGT19NF1102 KFGX19NM3020 KFGY19NF KFGY19NF1102 KFGY19NM3020 NDE007*G3018 NDE007*G4018 NDE807*F3022 NDE807*F5422 NDE807*G3018 NDE807*G4018 NDE907*F3022 NDE907*F5422 NDG809*F3022 NDG809*F5422 NDG909*F3022 NDG909*F5422 NFEL47*G4018 NFEL67*G4018 NFEX07*G3018 NFEX07*G4018 NFGL49*M3013 NFGX09*M3013 NSE817*F5422 NSE917*F3022 NSE917*F5422 NSEBXFGW301NW22 NSG919*F3022 NSGBXFGW301NW22 PDE807*G3018 PDE807*G4018 PDG809*M3013 SDE007*F SDE007*F1500 SDE007*F3000 SDE007*F4350 SDE007*G3018 SDE107*F SDE107*F1500 SDE107*F1724 SDE107*F3000 SDE107*F4350 SDE107*F5412 SDE107*F5417 SDE107*F99L6 SDE107*F99L7 SDE107*G3018 SDE107*G4018 SDE307*F SDE307*F1500 SDE407*F SDE407*F1500 SDE407*F3000 SDE407*F4350 SDE507*F SDE507*F1500 SDE607*F SDE607*F1500 SDE707*F SDE707*F1500 SDE807*F SDE807*F1500 SDE807*F3000 SDE807*F4350 SDE907*F SDE907*F1500 SDE907*F1724 SDE907*F3000 SDE907*F4350 SDE907*F5412 SDE907*G3018 SDE907*G4018 SDEA07*J SDEA07*J1500 SDEA07*J3000 SDEA07*J4350 SDEB07*J SDEB07*J1500 SDEBCRGS171TW02 SDEBXRGS171TW02 SDEC07*J SDEF07*J SDEF07*J1500 SDEF07*J4350 SDEH07*J SDEH07*J1500 SDESXRGS171TW02 SDET07*F SDET07*F1500 SDEX07*F SDEX07*F1500 SDEX07*F3000 SDEX07*F4350 SDEX07*G3018 SDEX07*G4018 SDEY07*F SDEY07*F1500 SDEZ07*F SDEZ07*F1500 SDG009*F SDG009*F3000 SDG009*F3058 SDG009*F3060 SDG109*F SDG109*F1124 SDG109*F3058 SDG109*F3060 SDG109*F5412 SDG109*F99L6 SDG109*F99L7 SDG109*G3013 SDG109*M3013 SDG309*F SDG409*F SDG409*F3000 SDG409*F3058 SDG509*F SDG609*F SDG709*F SDG809*F SDG809*F3060 SDG909*F SDG909*F1124 SDG909*F3060 SDG909*F5412 SDG909*M3013 SDGA09*J SDGB09*J SDGBCRGS111TW02 SDGBXRGS111TW02 SDGC09*J SDGF09*J SDGF09*J3060 SDGH09*J SDGSXRGS111TW02 SDGT09*F SDGX09*F SDGX09*F3000 SDGX09*F3060 SDGX09*M3013 SDGY09*F SDGZ09*F SFE107*F SFE407*F SFE507*F SFE507*F1500 SFE707*F SFEA07*G3018 SFEB07*J SFEF07*J SFEL07*G4018 SFEL67*G4018 SFET07*F SFEX07*F SFEX07*F3300 SFEX07*F4350 SFEX07*G3018 SFEX07*G4018 SFEX67*G4018 SFEY07*F SFEY07*G4018 SFEZ07*F SFG109*F SFG409*F SFG509*F SFG709*F SFGB09*J SFGF09*J SFGL09*M3013 SFGT09*F SFGX09*F SFGX09*M3013 SFGY09*F SFGZ09*F SGD109*F3000 SSE007*F SSE007*F1500 SSE007*F3000 SSE007*F4350 SSE007*F99H2 SSE107*F SSE107*F1500 SSE107*F1724 SSE107*F99L6 SSE107*F99L7 SSE107*G3018 SSE117*F SSE117*F1500 SSE117*F3000 SSE117*F4350 SSE117*F5412 SSE117*G3018 SSE307*F SSE307*F1500 SSE417*F SSE417*F3000 SSE417*F4350 SSE507*F SSE507*F1500 SSE517*F SSE517*F1500 SSE607*F SSE617*F SSE707*F SSE717*F SSE807*F SSE807*F1500 SSE807*F3000 SSE807*F4350 SSE807*G3018 SSE907*F SSE907*F1500 SSE907*F1724 SSE907*G3018 SSE917*F SSE917*F3000 SSE917*F4350 SSEA07*G3018 SSEA17*J SSEB07*J SSEB07*J1500 SSEB17*J SSEB17*J1500 SSEC07*J SSEF07*J SSEF17*J SSEF17*J4350 SSEH07*J SSEH07*J1500 SSET07*F SSET07*F1500 SSET17*F SSET17*F1500 SSEX07*F SSEX07*G3018 SSEY07*F SSEY07*F1500 SSEY17*F SSEZ07*F SSEZ07*F1500 SSEZ17*F SSEZ17*F1500 SSG009*F SSG109*F SSG109*F1124 SSG109*F99L6 SSG109*F99L7 SSG109*M3013 SSG119*F SSG119*F3000 SSG119*F3058 SSG119*F3060 SSG119*F5412 SSG119*F5480 SSG119*M3013 SSG309*F SSG419*F SSG419*F3000 SSG419*F3058 SSG509*F SSG519*F SSG609*F SSG619*F SSG709*F SSG719*F SSG809*F SSG909*F SSG909*F1124 SSG909*M3013 SSG919*F SSG919*F3060 SSGA19*J SSGB09*J SSGB19*J SSGC09*J SSGF09*J SSGF19*J SSGF19*J3060 SSGH09*J SSGT09*F SSGT19*F SSGX09*F SSGX09*M3013 SSGX19*F SSGX19*F3060 SSGY09*F SSGY19*F SSGZ09*F SSGZ19*F UDE007*F UDE007*F3000 UDE007*F3025 UDE807*F UDE807*F1702 UDG009*F UDG009*F3000 UDG009*F3025 UDG809*F UDG809*F1102 USE007*F USE017*F5412 USE807*F USG009*F USG019*F5412 PUB 505893R5 January 2016 Submitter Adirondack Bob Submitted 02/16/2018 Category Appliance Repair Manual Pot Luck Supper-

- troubleshooting

- dryer

-

(and 3 more)

Tagged with:

-

Speed Queen Alliance Single and Stacked Dryers- Troubleshooting Manual

Adirondack Bob posted a file in Appliance Repair Manual Pot Luck Supper

Version 1.0.0

323 downloads

Models BDE807*F BDE907*F BDEBEFGS171CN01 BDEBEFGS171CW01 BDEBEFGS171TN01 BDEBEFGS171TW01 BDEBLFGS431AW01 BDET07*F BDG809*F1102 BDG909*F1102 BDGBEFGS111CN01 BDGBEFGS111CW01 BDGBEFGS111TN01 BDGBEFGS111TW01 BDGBLFGS301AW01 BDGT09*F BFEL07*G4018 BFEX07*F BFEX07*F4350 BFEX07*G4018 BFGL09*M3013 BFGX09*F BFGX09*F3060 BFGX09*M3013 BSE807*F BSE907*F BSG809*F BSG909*F FDE807*G3018 FDE807*G4018 GDE807*F5418 GDE807*G3018 GDE907*G3018 GFEG17NG3018 GFEG17NG4018 GFEX17NG3018 GFEX17NG4018 GFEY17NG3018 GFEY17NG4018 GFGG19NM3020 GFGX19NM3020 GFGY19NM3020 HDE007*F HDE007*F1702 HDE007*F3000 HDE007*G3003 HDE007*G3008 HDE007*G3010 HDE007*G4008 HDE007*G4010 HDE107*F HDE107*F1502 HDE107*F1702 HDE107*F3000 HDE107*G3003 HDE107*G3018 HDE107*G4018 HDE507*F1502 HDE507*F1702 HDE707*F1502 HDE707*F1702 HDE807*F1702 HDE907*F HDE907*F1502 HDE907*F1702 HDE907*G3018 HDE907*G4018 HDEB07*J1502 HDEB07*J1702 HDEB07*J99L1 HDEB07*J99L2 HDEF07*J1502 HDEF07*J1702 HDER07*F1502 HDER07*F1702 HDET07*F HDET07*F1500 HDET07*F1502 HDET07*F1702 HDEX07*F1502 HDEX07*F1702 HDEX07*F3000 HDEX07*G3018 HDEY07*F HDEY07*F1500 HDEY07*F1502 HDEY07*F1702 HDEY07*F99N2 HDEZ07*F HDEZ07*F1500 HDEZ07*F1502 HDEZ07*F1702 HDG009*F HDG009*F1102 HDG009*F3000 HDG009*G3008 HDG009*M3008 HDG109*F HDG109*F1102 HDG109*F3000 HDG109*G3013 HDG109*M3013 HDG509*F1102 HDG709*F1102 HDG809*F1102 HDG909*F HDG909*F1102 HDGB09*J1102 HDGB09*J99L1 HDGF09*J1102 HDGR09*F1102 HDGT09*F HDGT09*F1102 HDGX09*F1102 HDGX09*F3000 HDGX09*M3013 HDGY09*F HDGY09*F1102 HDGZ09*F HDGZ09*F1102 HFE167*G4018 HFE507*F1702 HFE707*F1702 HFEB07*J1702 HFEL47*G4018 HFEL67*G4018 HFEX07*F1702 HFEY07*F1502 HFEY07*F1702 HFG509*F1102 HFG709*F1102 HFGX09*F1102 HFGX09*M3013 HFGY09*F1102 HSE117*F HSE117*F2802 HSE117*F2902 HSE517*F2802 HSE517*F2902 HSE717*F2802 HSE717*F2902 HSE917*F HSE917*F2802 HSE917*F2902 HSEB17*J1500 HSEB17*J2802 HSEB17*J2902 HSEB17*J99L1 HSEB17*J99L2 HSEF17*J2802 HSEF17*J2902 HSER17*F2802 HSER17*F2902 HSET17*F HSET17*F1500 HSET17*F2802 HSET17*F2902 HSEX17*F2802 HSEX17*F2902 HSEY17*F HSEY17*F1500 HSEY17*F2802 HSEY17*F2902 HSEY17*F99N2 HSEZ17*F HSEZ17*F1500 HSEZ17*F2802 HSEZ17*F2902 HSG119*F HSG119*F0902 HSG519*F0902 HSG719*F0902 HSG919*F HSG919*F0902 HSGB19*J0902 HSGB19*J99L1 HSGF19*J0902 HSGR19*F0902 HSGT19*F HSGT19*F0902 HSGX19*F0902 HSGY19*F HSGY19*F0902 HSGZ19*F HSGZ19*F0902 JDE807*F JDE807*F4350 JDE807*F5418 JDE807*G3018 JDE907*F JDE907*F4350 JDE907*G3018 JDEBEFGW301EW01 JDEBGFGW301EW01 JDEBGFSW301EN01 JDG809*F JDG809*F3060 JDG809*M3013 JDG809*M3020 JDG909*F JDG909*F3060 JDG909*M3013 JDG909*M3020 JDGBEFGW301EW01 JDGBGFGW301EW01 JDGBGFSW301EN01 JSE807*F JSE807*F4350 JSE907*F JSE907*F4350 JSEBEFGW301EW01 JSEBGFGW301EW01 JSG809*F JSG809*F3060 JSG909*F JSG909*F3060 JSGBEFGW301EW01 JSGBGFGW301EW01 KFEG17NF KFEG17NF1702 KFEG17NG3018 KFEG17NG4018 KFET17NF KFET17NF1702 KFEX17NG3018 KFEX17NG4018 KFEY17NF KFEY17NF1702 KFEY17NG3018 KFEY17NG4018 KFGG19NF KFGG19NF1102 KFGG19NM3020 KFGT19NF KFGT19NF1102 KFGX19NM3020 KFGY19NF KFGY19NF1102 KFGY19NM3020 NDE007*G3018 NDE007*G4018 NDE807*F3022 NDE807*F5422 NDE807*G3018 NDE807*G4018 NDE907*F3022 NDE907*F5422 NDG809*F3022 NDG809*F5422 NDG909*F3022 NDG909*F5422 NFEL47*G4018 NFEL67*G4018 NFEX07*G3018 NFEX07*G4018 NFGL49*M3013 NFGX09*M3013 NSE817*F5422 NSE917*F3022 NSE917*F5422 NSEBXFGW301NW22 NSG919*F3022 NSGBXFGW301NW22 PDE807*G3018 PDE807*G4018 PDG809*M3013 SDE007*F SDE007*F1500 SDE007*F3000 SDE007*F4350 SDE007*G3018 SDE107*F SDE107*F1500 SDE107*F1724 SDE107*F3000 SDE107*F4350 SDE107*F5412 SDE107*F5417 SDE107*F99L6 SDE107*F99L7 SDE107*G3018 SDE107*G4018 SDE307*F SDE307*F1500 SDE407*F SDE407*F1500 SDE407*F3000 SDE407*F4350 SDE507*F SDE507*F1500 SDE607*F SDE607*F1500 SDE707*F SDE707*F1500 SDE807*F SDE807*F1500 SDE807*F3000 SDE807*F4350 SDE907*F SDE907*F1500 SDE907*F1724 SDE907*F3000 SDE907*F4350 SDE907*F5412 SDE907*G3018 SDE907*G4018 SDEA07*J SDEA07*J1500 SDEA07*J3000 SDEA07*J4350 SDEB07*J SDEB07*J1500 SDEBCRGS171TW02 SDEBXRGS171TW02 SDEC07*J SDEF07*J SDEF07*J1500 SDEF07*J4350 SDEH07*J SDEH07*J1500 SDESXRGS171TW02 SDET07*F SDET07*F1500 SDEX07*F SDEX07*F1500 SDEX07*F3000 SDEX07*F4350 SDEX07*G3018 SDEX07*G4018 SDEY07*F SDEY07*F1500 SDEZ07*F SDEZ07*F1500 SDG009*F SDG009*F3000 SDG009*F3058 SDG009*F3060 SDG109*F SDG109*F1124 SDG109*F3058 SDG109*F3060 SDG109*F5412 SDG109*F99L6 SDG109*F99L7 SDG109*G3013 SDG109*M3013 SDG309*F SDG409*F SDG409*F3000 SDG409*F3058 SDG509*F SDG609*F SDG709*F SDG809*F SDG809*F3060 SDG909*F SDG909*F1124 SDG909*F3060 SDG909*F5412 SDG909*M3013 SDGA09*J SDGB09*J SDGBCRGS111TW02 SDGBXRGS111TW02 SDGC09*J SDGF09*J SDGF09*J3060 SDGH09*J SDGSXRGS111TW02 SDGT09*F SDGX09*F SDGX09*F3000 SDGX09*F3060 SDGX09*M3013 SDGY09*F SDGZ09*F SFE107*F SFE407*F SFE507*F SFE507*F1500 SFE707*F SFEA07*G3018 SFEB07*J SFEF07*J SFEL07*G4018 SFEL67*G4018 SFET07*F SFEX07*F SFEX07*F3300 SFEX07*F4350 SFEX07*G3018 SFEX07*G4018 SFEX67*G4018 SFEY07*F SFEY07*G4018 SFEZ07*F SFG109*F SFG409*F SFG509*F SFG709*F SFGB09*J SFGF09*J SFGL09*M3013 SFGT09*F SFGX09*F SFGX09*M3013 SFGY09*F SFGZ09*F SGD109*F3000 SSE007*F SSE007*F1500 SSE007*F3000 SSE007*F4350 SSE007*F99H2 SSE107*F SSE107*F1500 SSE107*F1724 SSE107*F99L6 SSE107*F99L7 SSE107*G3018 SSE117*F SSE117*F1500 SSE117*F3000 SSE117*F4350 SSE117*F5412 SSE117*G3018 SSE307*F SSE307*F1500 SSE417*F SSE417*F3000 SSE417*F4350 SSE507*F SSE507*F1500 SSE517*F SSE517*F1500 SSE607*F SSE617*F SSE707*F SSE717*F SSE807*F SSE807*F1500 SSE807*F3000 SSE807*F4350 SSE807*G3018 SSE907*F SSE907*F1500 SSE907*F1724 SSE907*G3018 SSE917*F SSE917*F3000 SSE917*F4350 SSEA07*G3018 SSEA17*J SSEB07*J SSEB07*J1500 SSEB17*J SSEB17*J1500 SSEC07*J SSEF07*J SSEF17*J SSEF17*J4350 SSEH07*J SSEH07*J1500 SSET07*F SSET07*F1500 SSET17*F SSET17*F1500 SSEX07*F SSEX07*G3018 SSEY07*F SSEY07*F1500 SSEY17*F SSEZ07*F SSEZ07*F1500 SSEZ17*F SSEZ17*F1500 SSG009*F SSG109*F SSG109*F1124 SSG109*F99L6 SSG109*F99L7 SSG109*M3013 SSG119*F SSG119*F3000 SSG119*F3058 SSG119*F3060 SSG119*F5412 SSG119*F5480 SSG119*M3013 SSG309*F SSG419*F SSG419*F3000 SSG419*F3058 SSG509*F SSG519*F SSG609*F SSG619*F SSG709*F SSG719*F SSG809*F SSG909*F SSG909*F1124 SSG909*M3013 SSG919*F SSG919*F3060 SSGA19*J SSGB09*J SSGB19*J SSGC09*J SSGF09*J SSGF19*J SSGF19*J3060 SSGH09*J SSGT09*F SSGT19*F SSGX09*F SSGX09*M3013 SSGX19*F SSGX19*F3060 SSGY09*F SSGY19*F SSGZ09*F SSGZ19*F UDE007*F UDE007*F3000 UDE007*F3025 UDE807*F UDE807*F1702 UDG009*F UDG009*F3000 UDG009*F3025 UDG809*F UDG809*F1102 USE007*F USE017*F5412 USE807*F USG009*F USG019*F5412 PUB 505893R5 January 2016-

- 505893

- speed queen

-

(and 3 more)

Tagged with:

-

Introduction to using the Pressure-Enthalpy Chart to diagnose refrigerator sealed system problems

Samurai Appliance Repair Man posted a file in Appliance Repair Manual Pot Luck Supper

Version 1.0.0

45 downloads

This is an excellent short (14 pages) technical article written by Dave Demma, a Senior Application Engineer with Sporlan. He explains how to use the pressure-enthalpy (P-H) chart to understand how a refrigeration cycle works and how to apply this to various troubleshooting scenarios. Don't let the "engineer" scare you-- the math is minimal and simple, nothing more complicated than arithmetic: adding, subtracting, multiplying, and dividing. The explanations are clear, plain and non-geeky and he uses lots of illustrations. It really is a masterpiece of teaching and making something complex understandable by anyone, regardless of your technical background. If you understand or are at least familiar with the P-H chart (which we covered in detail in the Refrigerator Sealed System Thermodynamics webinar series), you'll get a much better understanding for saturation, superheat, subcooling, and system pressures. This copy has my highlights of key points.-

- p-h diagram

- sealed system

-

(and 1 more)

Tagged with:

-

New Appliance Service Manual added: Introduction to using the Pressure-Enthalpy Chart to diagnose refrigerator sealed system problems

Samurai Appliance Repair Man posted a topic in Appliance Service Manual Requests Forum

Introduction to using the Pressure-Enthalpy Chart to diagnose refrigerator sealed system problems View File This is an excellent short (14 pages) technical article written by Dave Demma, a Senior Application Engineer with Sporlan. He explains how to use the pressure-enthalpy (P-H) chart to understand how a refrigeration cycle works and how to apply this to various troubleshooting scenarios. Don't let the "engineer" scare you-- the math is minimal and simple, nothing more complicated than arithmetic: adding, subtracting, multiplying, and dividing. The explanations are clear, plain and non-geeky and he uses lots of illustrations. It really is a masterpiece of teaching and making something complex understandable by anyone, regardless of your technical background. If you understand or are at least familiar with the P-H chart (which we covered in detail in the Refrigerator Sealed System Thermodynamics webinar series), you'll get a much better understanding for saturation, superheat, subcooling, and system pressures. This copy has my highlights of key points. Submitter Samurai Appliance Repair Man Submitted 01/30/2018 Category Appliance Repair Manual Pot Luck Supper-

- p-h diagram

- sealed system

-

(and 1 more)

Tagged with:

-

[Webinar - Rescheduled] Sealed System Mastery using Basic Thermodynamics

Son of Samurai posted an event in Tech Training

untilNote: This webinar was rescheduled from its original date on October 30 to November 6. Be sure to subscribe to our newsletter for updates! Who: Professional Appliantologists, Senior Appliantology Fellows, and Legacy Tech members at Appliantology Master Samurai Tech Academy students enrolled in the Refrigerator Repair course Mr. Appliance® Academy students enrolled in Bundle 1 What: Practical Sealed System Thermodynamics In the last session on 10-2-2017, we laid the theoretical groundwork for understanding how sealed systems do what they do: move heat from a refrigerated compartment to the outside world. We looked at basic refrigeration concepts like pressure energy work enthalpy entropy saturation superheat subcooling and we got acquainted with the P-H diagram which we used to understand the ideal refrigeration cycle. We looked at the thermodynamic states of the refrigerant throughout the cycle: compression, condensing, expansion, and evaporation. Then we looked at a real-world refrigeration cycle with temperature and pressure measurements around the system and plotted it on a P-H diagram. We left off with a homework assignment where we're given pressure and temperature measurements around a refrigeration system and we have to determine what state the refrigerant is in: liquid, vapor, mix, saturated, superheated, or subcooled. This is where we'll pick up in this webinar. Having laid some theoretical groundwork in the last webinar, we're going to focus on practical considerations in this one. That means quick n’ dirty techniques for diagnosing sealed system problems using strategically chosen and skillfully interpreted temperature measurements. Here's what we'll be doing: Brief review of the Pressure-Temperature relationship in sealed systems Review homework from the first session on 10-2-2017. Home refrigerator practical design and operating rules-of-thumb useful for troubleshooting Practical application exercises Troubleshooting scenario exercise Techniques for making system temperature measurements for determining superheat and subcooling Sealed system diagnosis homework assignment (to be reviewed in the next webinar in this series) If you attended the first webinar in this series, this is your payday! We’re going to apply that keen, penetrating insight you now possess into money- and time-saving shortcuts you can use to diagnose real-world refrigeration systems on service calls. Also, make sure to do the homework assignment because this will let you test yourself to see whether you understood the key concepts or not. We're going to be proceeding on the assumption that you understand basic concepts like phase change, saturation, superheat, subcooling, etc. If you did not attend the first webinar or haven't watched the two-part webinar recordings of them, you are still welcome to attend, but may be baffled by parts of this one. When: Monday, October 30, 2017, at 7PM Eastern Time SHARP (adjust your time zone accordingly). Where: All of our web meetings are powered by Join.me. For the connection details, see below. Master Samurai Tech Academy Students: RSVP here. Mr. Appliance® Academy Bundle 1 Students: RSVP here. Professional Appliantologists, Senior Appliantology Fellows, and Legacy Techs: fill out the form below to request connection details:<a data-cke-saved-href="https://mastersamuraitech.wufoo.com/forms/mur05y20li0deq/" href="https://mastersamuraitech.wufoo.com/forms/mur05y20li0deq/">Fill out my Wufoo form!</a> How: Here are three tips to ensure that the webinars are a smooth, cool experience for you: Arrive early to make sure your connection is working! Also, if you show up late for the webinar, you'll be lost. Enter your name at the "knock to enter" window on the meeting page- if you leave it blank, you won't be able to enter. Watch this ultra-short video on how to use your Join.me control console.- 2 comments

-

- short cuts

- troubleshooting

- (and 4 more)

-

Free Short Course from the Master Samurai Tech Academy: The Ten Step Tango Troubleshooting Procedure

Samurai Appliance Repair Man posted a blog entry in Samurai Appliance Repair Man's Blog

Troubleshooting is the big missing skill among appliance techs today. In fact, many techs don’t even know what troubleshooting is and mistake pattern recognition and factoids for real troubleshooting. Classical troubleshooting is a structured and scientific method for thinking and solving appliance problems. There is a method to the madness! The Master Samurai Tech troubleshooting method is called the Ten Step Tango (TST). There are specific dance steps to troubleshooting, and we teach them to anyone who wants to learn. As an introduction to the TST, we’re offering a free short course to the entire appliance tech community where techs can quickly learn the TST troubleshooting procedure and immediately start benefitting from this skill on service calls. The TST short course uses a real-world, modern refrigerator (dual evaporator, computer-controlled) case study to lead you through each of the ten steps in the TST to troubleshoot and solve the problem. To get started, just register a free account at the Master Samurai Tech Academy, and you'll see the “Ten Step Tango Troubleshooting Procedure Case Study” listed as one of your free courses available to you on your login welcome page. If you're already registered at the Academy, just log in as usual and you'll see the course on your login welcome page. You'll also be able to take our other free courses: Appliantology 101 and Internetology. All our free courses are short and fun to do. So have fun, dammit!-

- master samurai tech

- troubleshooting

- (and 2 more)